Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

The cast basalt stone tubes or tiles are bonded onto the internal surface of the steel pipe properly to a form a wear resistant cast basalt stone lined pipe / elbow. The combination of high rigidity of ceramic and high elasticity of steel gives the pipe unmatchable features as an abrasion resistant, heat resistant and corrosion resistant material used in the variety of industries.

Cast Basalt is a mineral of exceptionally high abrasion resistance, unlimited resistance to moisture, high compressive strength and resistance to virtually all acids and alkalis and is completely corrosion free. Cast blast is produced by melting selected natural basalt broken into sizes of 20-50 mm in shaft furnaces at temperatures around 1,300C, following by casting at which the melted basalt forms uniforms pherolithic crystals hence producing its typical physical properties, in particular its exceptional hardness and wear-resistance.

Cast basalt reaches a value of hardness of 8(min) on the Moh’s hardness scale. For comparison: the highest value10is only attained by diamonds. By virtue of these properties, the silicate cast basalt provides outstanding protection against abrasion and scrubbing.

However, it is marked by ascertain sensitivity to impacts. Under Normal services conditions, cast basalt withstands temperatures up to approx. + 350C or-40C. However Cast basalt should not be subjected to temperature shocks.

Sizes: Cast basalt produces are manufactured as tiles, from pieces and segments. Straight pipes are spun-cast, available for nominal bores of 32 to 600 mm with the wall thickness ranging from 20 to 30mm and a standard length of 500mm.samller nominal bores of straight pipes, pipe segment for radial of 40 to 3,000mm of various angles, as well as special form piece linings are predominantly sand-cast. The standard wall-thickness is 20mm. depending on the respective quantity, steel moulds can also be used, the wall thickness in those cases usually being 30 to 40mm.

Hard & Compact Smooth & Inner Withstands High-Abrasion & Corrosion In any of the process industries especially Sled and Cement corrosion and abrasion lead to significant downtime of the plant. Further, the useful life or the equipment itself may get impaired because of the high abrasive nature of the materials being used. Thus, ‘wear mechanism’ results in hut down, replacement, etc., which is costly, resulting in loss to tilt: tunic of millions of rupees.

| Material | Thickness(mm) | Approx. Life ( Months ) |

|---|---|---|

| Mild Steel | 10 | 3-5 |

| Cast Iron | 20 | 6-8 |

| Ni-Hard | 20 | 12-14 |

| Cast Basalt | 30 | 20-25 |

| Ceramic | 10 | 35-40 |

Technical Details:

We hold expertise in fabricating and supplying of a qualitative range Cast Basalt coated Ash Pipelines. Our pipelines are designed and developed by experts to ensure durability and also to meet International Quality Standards. Our Ash Pipelines are coated with Cast Basalt to prevent abrasion because cast basalt is one of the most frequently used wear protection materials. The range of Ash Pipelines made by us are highly acknowledged in the market due to their excellent performance and salient features including excellent wear & tear, durability, reliability, high strength, and cost-effectiveness.

At Reli Sleeve, we lined up Ash bends with Cast basalt because is wear resistant and makes the bends more durable. It possess superior properties such as Hardness (7 to 8 MOH), Scale Compressive Strength (4500 Kg/Sq. cm), Abrasive Resistance (0.06 – 0.08 cm) Bending Strength (300 Kg/Sq. cm), Temperature Limit (350°C) and nil Water Absorption. Due to such properties it is more preferable lining than others. These Cash Basalt coated Ash bends find application in various industries. Moreover, these are highly acknowledged for their salient features such as: high strength, durability, excellent wear & tear, and reasonable prices.

Available Variants:

We offer Cast Basalt Tiles for Coal Bunkers and Chutes. These cast basalt tiles are bedded as well as jointed in cement/special bonding agents like resins depending upon application. These tiles mostly find application in automotive industry and are designed to provide long-lasting lining and enhancement to involved operational life cycle for both plant as well as equipment. Other than automobiles, some of the other industries where these are used in include:

Available Variants:

Advantages:

Following types of liners are under our production range:-

1.Trench Liners

Trench Liners have proven to be the perfect solution of erosion problems. The trench liners are custom fabricated according to the specific dimensions of each trench to facilitate installation.

2. Hexagonal Liners

Hexagonal and small square tiles ranging from 10 sq. mm to 20 sq. mm in thickness ranging from 5mm to 15mm are manufactured form small curves and fast In-situ application. In case of high impact conditions, Hexagonal Tiles with Rubber Armour is provided.

3. Rectangular Plates/Tiles

Various types of rectangular plates or tiles are under our manufacturing range

Good abrasion resistance

As the wear surface, the cast basalt ceramic is 8 Mohs hardness, whose wear resistance is 10 times that of hi-chrome cast iron alloy pipes. It can make a little wear loss of the pipe during running, which extend the service life of the equipment largely.

Good thermal stability and excellent corrosion resistance

-50-350 ℃ is ideal temperature for the cast basalt ceramic lined pipe, and the inner wall of the pipe is cast basalt plates or tubes which have unique chemical properties of wonderful acid and alkali resistance.

Light Weight

The density is 3.63g/cm³, which is only half of the steel to reduce the load of the equipment largely.

Easy and fast to fix on site

Welding, flange, flexible joint are available for fix with the equipment.

All the performance of Anti-wear cast stone lined steel pipe / cast basalt lining composite tube makes low project costs, the charges can be about 20-30% less than wear steel piping project.

Normal Specification

Full range of Anti-wear cast stone lined steel pipe / cast basalt lining composite tube including straight pipes, bends, elbows, tees,Y-pieces, reducers,crosses and etc can be available from our factory.

Regarding the connection ways, we can provide with the normal way of welding or flange or to customize according to the customer’s requirements.

| Material | Thickness(mm) | Approx life ( Months ) |

|---|---|---|

| Mild Steel | 10 | |

| Cast Iron | 20 | |

| Ni-Hard | 20 | |

| Cast Basalt | 30 | 20-25 |

| Ceramic | 10 | 35-40 |

Basalt is a dark, dense-looking rock, often with small porphyritic crystals, and weathering to a brown colour on exposed surfaces. It is the commonest of all lavas, the basalt flows of the world being estimated to have five times the volume of all other extrusive rocks together. Basalt also forms small intrusions.

Basalt casts are considered the best lining materials for industries dealing with abrasion resistance.

| SiO2 | Al2O2 | Fe2O3 | TiO2 | CaO | MgO | K2O | Na2O | FeO | P2O5 |

|---|---|---|---|---|---|---|---|---|---|

| 43.13-41.12 | 12.5-13.52 | 8.64-9.5 | 2.02-2.62 | 9.05-10.22 | 8.65-10.47 | 1.4-1.75 | 4.62-5.28 | 4.82-6.25 | 1.1-1.38 |

The excellent performance of cast basalt lined steel pipe is that it sets tenacity of steel pipe, abrasive resistance of cast basalt pipe, concreteness of cement mortar in one.

This greatly improves the products adaptive capacity in complicated operation conditions. At the same time. Cement mortar is selected as the filling material and this can make the inside surface of steel pipe in alkali mediums. So the surface of steel pipe generates purifying films. These films can prevent being rusted.

| Category | Attribute |

|---|---|

| Density | 3g/cm3 |

| Compressive Strength | ≥ 450MPa |

| Bending strength | ≥ 60MPa |

| Impact strength | 1.76KJ/M2 |

| Abrasive strength | 0.07g/cm2 |

| Vickers scale | ≥ 720kg/mm |

| Elasticity modulus | 1.67x105MPa |

| Dilatation coefficient (60℃) | 8.92x10-6 |

| Chemical Attack Resistance | |

| 95%-98% H2SO4 | ≥ 98% |

| 20%H2S4 | ≥ 94% |

| 20 %NaOH | ≥ 98% |

Cast basalt pipes owing to an excellent performance of abrasive and corrosion resistance .It may be used as the liner of pipeline for hydraulic,pneumatic of conveyance of material and corrosion materials or slurry.We can offer the basalt pipes with nominal diameter of 40mm-800mm.

Cast Basalt can be used for the lining of pipework, chutes, bunkers, cyclones, and hoppers. It has become the global standard in areas such as ash slurry pipework, often used at fossil-fuel power stations. It is an all-round cost-effective and adaptable lining material that extends the life of equipment in the pipe or tile form where affected by erosion.

Cast Basalt is well-proven in a variety of industries as a cost-effective, long-lasting lining material used to extend the operating life of equipment manufactured or lined with lower-wearing materials such as steel, cast iron, rubber, and polyurethane.

Cast basalt lined steel pipe, as both a wear—resistant and corrosion—resistant materials, the transport properties of wear or corrosion of materials, after thirty years of practical verification, cast basalt lined steel pipe can be well done.

Cast basalt is also used in cement plants for making air separators, chain conveyor, silica hoppers, nozzles, coal hoppers, cement hoppers, cyclones, raw mill ducts, chutes, thick slurry lines, mixers, grate cooler housing, coal ventury etc.

Cast basalt pipes have an excellent performance of abrasive resistant and corrosion resistant, can be used as the pipeline lining in conveying wearable materials and corrosion materials. Such as: electric power plant, chemical plant, metallurgy industry, mine and so on.

Cast Basalt Composite Pipes Used for Years

Cast basalt pipe adopts foam packaging, then in accordance with the specifications to put them into wooden cases, sometimes they can be directly loaded into the compartment or container.

Cast basalt pipe adopts foam packaging, then in accordance with the specifications to put them into wooden cases, sometimes they can be directly loaded into the compartment or container.

Cast basalt lined pipes and fittings can be supplied with different and connections as per the design requirement to suit the site conditions and easy installation.

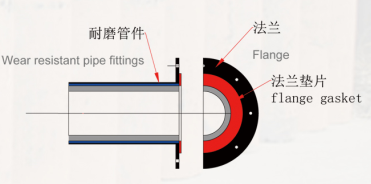

As a standard production, we supply flanged components according to DIN, with at least one movable flange for easy mounting, but pipes with plain ends or for custom coupling are also available. Flange Connection Is One Kind Of Common Pipeline Installation Connections. By Two Pieces Of Flanges, Pipeline, Valve, Equipments Are Connected And It Forms A Tight Piping System. When Pipeline Pressure Is Larger, Flange Connection Is Priority Selection. Flanges Have Lots Of Different Sizes. Flange Size Is Determined According To Pipeline Normal Diameter And Pipeline Operation Pressure.

The parameters of the outside steel pipe will be decided according to the working pressure of the system. The connection of the pipes and fitting will be of flange connections, easy—flexible joint connection or by welding.

By two pieces of flanges, pipeline, valve, equipments are connected and it forms a tight piping system. When pipeline pressure is larger, flange connection is priority section. Flanges have lots of different sizes.

Flange size is determined according to pipeline normal diameter and pipeline operation pressure.

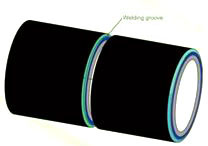

It suits short Distance Pipeline System Without Maintenance. It Is One Kind Of Common Installation Connections. It Requires Installation Personnel Higher Welding Ability. It Also Restricts By Welding Site, Distance, Welding Positions. Welding Connections Is Inconvenient In Later Maintenance.

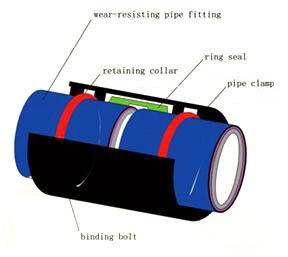

It Is One Of High Efficient And Rapid Installation Connection. I T Has The Below Characteristic: Easily Install And Disassemble, Fast Installation, Temperature Adjustable Compensation Function, Saving The Necessary Expansion In Long Pipeline. Easy-Flexible Joint Also Has Angle Compensation Characteristic. At Smaller Angle Turning Points, Easy-Flexible Joint Can Be Instead Of Bends And Adjust Angle.

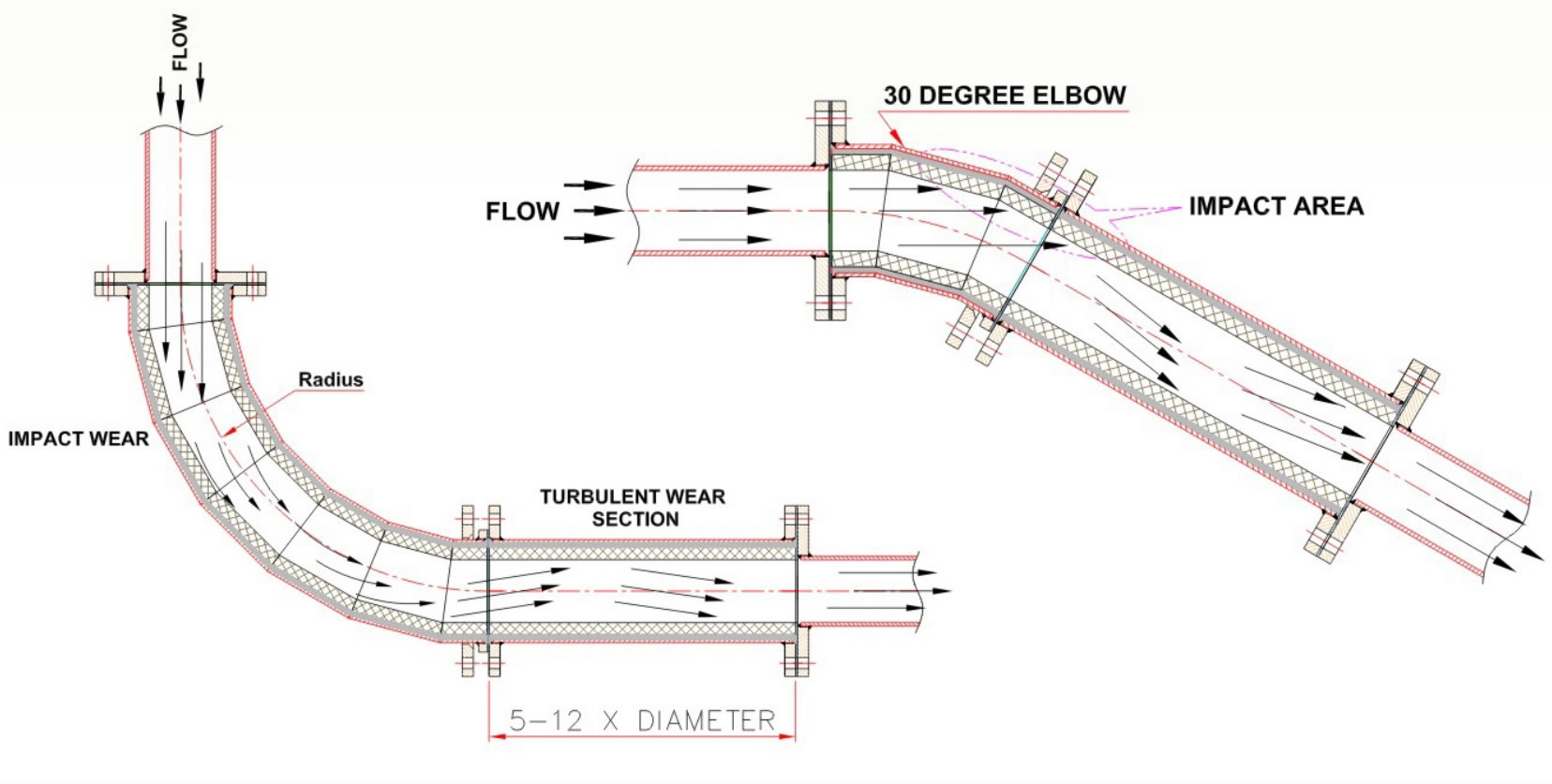

1. The bend radius should be minimum 3 times of the nominal bore.

2. At discharge end of each bend, cast basalt lined straight pipe of length 5 to 12 times the nominal bore must be used.

Need to inquire about our products? Fill out the form below and our staff will be in touch!

Q: How long is your delivery time?

A: The delivery time of customized products is generally 25 35 days, and non customized products are generally shipped within 24 hours after payment.

Q: Do you provide samples? Is it free?

A: If the value of the sample is low, we will provide it for free, but the freight needs to be paid by the customer. But for some high value samples, we need to charge a fee.

Q: What are your payment terms?

A: T/T 30% as the deposit,The balance payment is paid in full before shipment

Q: What is the packaging and transportation form?

A: Non steaming wooden box and iron frame packaging. Special packaging is available according to customer needs. The transportation is mainly by sea.

Q: What is your minimum order quantity?

A: There is no minimum order quantity requirement. Customized products are tailor made according to the drawings provided by the customer.