Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Double Submerged Arc Welded (DSAW) steel pipe is available in straight and spiral welded formats and used in a variety of applications.

Double Submerged Arc Welded (DSAW) steel pipe is available in straight and spiral welded formats and used in a variety of applications. The submerged welding process protects the steel from contamination of impurities in the air.

DSAW pipe can be specified in very large diameter and to exact inside or outside dimensions. Spiral Welded steel pipe is distinguished by the manufacturing process that results in a spiral DSAW seam the length of the pipe to lengths of 155 feet.

The manufacturing of Double Submerged Arc Welded Pipe involves first forming steel plates into cylindrical shapes. Then the edges of the rolled plate are formed so that V-shaped grooves are formed on the interior and exterior surfaces at the location of the seam. The pipe seam would then be welded by a single pass of an arc welder on the interior and exterior surfaces. The welding arc is submerged under flux. What can be known as an advantage of this process is that welds would penetrate 100% of the pipe wall and produce a very strong bond of the pipe.

Full Supply Ltd have been supplying EFW Electric Fusion Welded Pipe for many years.

Full Supply Ltd have been supplying EFW Electric Fusion Welded Pipe for many years.

Spiral steel pipe is a spiral seam steel pipe made of strip steel coils as raw materials, often extruded and formed by automatic double-wire double-sided submerged arc welding.

(1) Raw materials are strip steel coils, welding wires, and fluxes. Strict physical and chemical tests are required before investment.

(2) Butt joint of strip steel head and tail, adopt single wire or double wire submerged arc welding, after coiling into steel pipe, adopt automatic submerged arc welding repair welding.

(3) Before forming, the strip undergoes leveling, edge trimming, edge planing, surface cleaning and conveying, and pre-bending treatment.

(4) The electric contact pressure gauge is used to control the pressure of the cylinders on both sides of the conveyor to ensure the smooth conveying of the strip.

(5) Adopt external control or internal control roll forming.

(6) The weld gap control device is used to ensure that the weld gap meets the welding requirements, and the pipe diameter, the amount of misalignment, and the weld gap are all strictly controlled.

(7) Both internal welding and external welding adopt the American Lincoln electric welding machine for single-wire or double-wire submerged arc welding to obtain stable welding specifications.

(8) The welded seams after welding are all inspected by an online continuous ultrasonic automatic flaw instrument, which guarantees 100% non-destructive testing coverage of spiral welds. If there is a defect, it will automatically alarm and spray the mark, and the production workers can adjust the process parameters at any time to eliminate the defect in time.

(9) Use an air plasma cutting machine to cut the steel pipe into individual pieces.

(10) After cutting into single steel pipes, the first three steel pipes of each batch shall be subject to a strict first inspection system to check the mechanical properties, chemical composition, fusion status of the welds, the surface quality of the steel pipes, and pass non-destructive inspections to ensure the pipe manufacturing process Only after it is qualified can it be officially put into production.

(11) The parts with continuous sonic flaw detection marks on the weld are re-examined by manual ultrasonic and X-ray. If there are defects, after repairing, they will go through non-destructive inspection again until the defects are confirmed.

(12) The pipes where the strip butt welds and the D-shaped joints intersecting the spiral welds are all inspected by X-ray television or filming.

(13) Each steel pipe undergoes a hydrostatic pressure test, and the pressure adopts a radial seal. The test pressure and time are strictly controlled by the steel pipe hydraulic microcomputer detection device. The test parameters are automatically printed and recorded.

(14) The pipe end is mechanically processed to accurately control the verticality, bevel angle, and obtuse edge of the end face.

Double submerged arc welded spiral steel pipe with its high pressure capacity, small resistance, low temperature resistance, corrosion resistance, easy installation and maintenance, etc., is more and more oil and gas, slurry transportation, urban construction and other industries welcome.

I. double submerged arc welding process, the plate deformation uniformly small, residual stress, surface does not produce scratches. Processing of pipe diameter and wall thickness of the pipe sizes range, greater flexibility, especially in the production of high-grade steel thick-walled steel pipe, large diameter thick wall pipe has the incomparable advantage of other technology, to meet the users in pipe size requirements;

Ⅱ. Presoldering outside welding (the fine welding) the process can be implemented in the best position welding, less prone to the wrong side of the welding partial and incomplete penetration defects such as welding quality, easy to control;

Ⅲ. Overall mechanical enlarged diameter, which can effectively improve the dimensional accuracy of a steel pipe, and improve the distribution state of the stresses in the steel pipe, thus avoiding the damage caused due to stress corrosion, is also conducive to the welded construction of the scene;

Ⅳ. 100% quality check on the steel, so that the whole process of pipe production are effective detection, monitored, to ensure the product quality of the SAW pipe;

Ⅴ. Entire production line equipment have networked with a computer data acquisition system to realize the real-time transmission of data, the quality of the technology in the production process parameters and quality indicators adopted by the central control room.

Double submerged arc welded straight seam steel pipe is a new welding method invented in 1940, it is the same place and the front of the manual welding it or slag protection, but this residue is not the electrode coating, but melting out welding flux.

Flux system consists of a funnel filled with flux transported through a pipeline to the front to be welded. The second difference is not electrode, wire, because the wire can be continuously sent to; electrode, we burn an electrode must have a welding rod head gave throw, and the operation is stopped, and then change electrode welding.

After the wire is changed, with a means to send the wire and the wire for rent, gave continuous welding wire, welding wire is continuously fed, covered with a granular flux can be melted under the ignition of the arc, the welding wire, base material and part of the melting and evaporation of the flux constitute a cavity arc inside the cavity stable combustion, it called submerged arc welding. The arc is buried in the cavity inside.

The advantages of the double submerged arc welded

Pipe is a high-strength steel, this first prefabricated section of pipe at the factory inside, and then get on the site, field welding, the welding process is the use of this pipeline in the factory to make a submerged arc welding, submerged arc welding has developed into a double wire submerged arc welding, as well as multi-wire submerged arc welding, to further improve the efficiency.

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

|---|---|---|---|

| Electric-Resistance-Welded Steel Pipes | ASTM A135 | 42.2-114.3 x 2.11-2.63 | A |

| Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes | ASTM A178 | 42.2-114.3 x 2.11-2.63 | A, C,D |

| ERW and Hot-dip Galvanized Steel Pipes | ASTM A53 | 21.3-273 x 2.11-12.7 | A, B |

| Pipes for Piling Usage | ASTM A252 | 219.1-508 x 3.6-12.7 | Gr2, Gr3 |

| Tubes for General Structural Purpose | ASTM A500 | 21.3-273 x 2.11-12.7 | Carbon Steel |

| Square Pipes for General Structural Purpose | ASTM A500 | 25 x 25-160 x 160 x 1.2-8.0 | Carbon Steel |

| Mechanical tubing | ASTM A513 | 21.3-273 x 2.11-12.7 | carbon and alloy steel |

| Screwed and Socketed Steel Tubes | BS 1387 | 21.4-113.9 x 2-3.6 | Carbon Steel |

| Scaffolding Pipes | EN 39 | 48.3 x 3.2-4 | Carbon Steel |

| Carbon Steel Tubes for General Structure Purpose | JIS G3444 | 21.7-216.3 x 2.0-6.0 | Carbon Steel |

| Carbon Steel Tubes for Machine Structure Purpose | JIS G3445 | 15-76 x 0.7-3.0 | STKM11A, STKM13A |

| Carbon Steel Pipes for Ordinary Piping | JIS G3452 | 21.9-216.3 x 2.8-5.8 | Carbon Steel |

| Carbon Steel Pipes for Pressure Service | JIS G3454 | 21.7-216.3 x 2.8-7.1 | Carbon Steel |

| Carbon Steel Rigid Steel Conduits | JIS G8305 | 21-113.4 x 1.2-3.5 | G16-G104, C19-C75, E19-E75 |

| Carbon Steel Rectangular Pipes for General Structure | JIS G3466 | 16 x 16-150 x 150 x 0.7-6 | Carbon Steel |

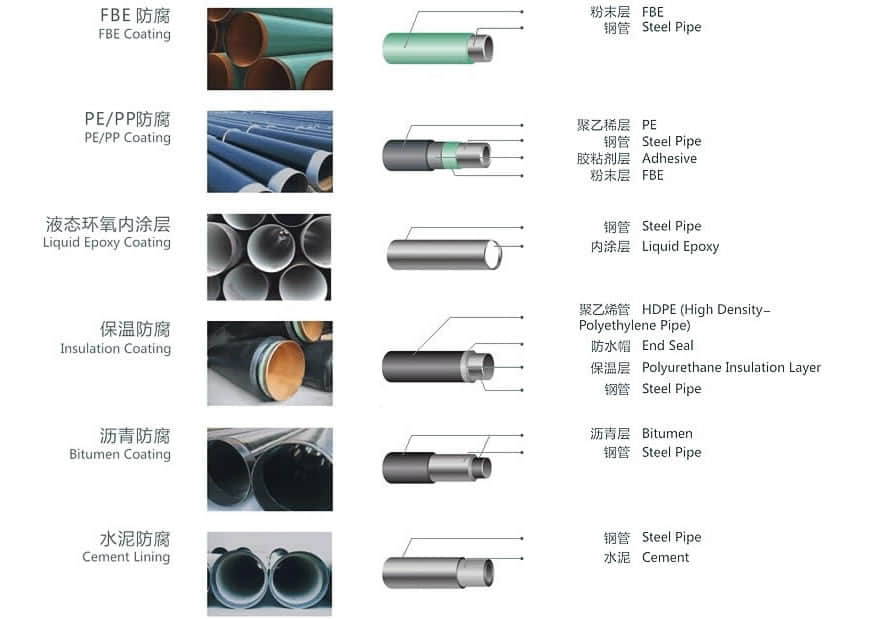

Pipeline coating is the most consistent and successful solution for protecting ERW pipes from corrosion, from moisture, other harmful chemicals.

Anti-corrosion steel pipe is processed through the preservation process, which can effectively prevent or slow down the process in the transport and use of chemical or electrochemical corrosion reaction of steel pipe.

Therefore pipe anti-corrosion layer is an important barrier to prevent soil erosion. A well-known foreign scholar put forward” 3PE france protective layer”, so far, anti-corrosion methods is widely used.

Coated pipes offer high resistance to corrosion on pipes and provide many benefits such as:

1. Increased Flow Capacity – A coating on pipes helps provide a smoother surface thus improving gas and liquid flow within pipes.

2. Reduced Cost – The pipeline coating increases the pipes durability so they can be deployed with minimum maintenance cost even in the harshest environments.

3. Lower energy usage – Various studies have shown that pipelines that are internally coated use less energy for pumping and compression of products through pipes. This helps in increased saving over time.

4. Clean delivery of products – The inhibitors used for the protection products can also be minimized by the use of coated pipes for delivery of products.

Thus, coating of pipelines can help you in reducing your maintenance cost and at the same time providing a corrosion free reliable protection.

The basic principles of urban gas pipeline coating selection:

2.1.External Coating

2.1.1 External Epoxy Coating

2.1.2 Polyethylene Coating

2.1.3 Polypropylene Coating

2.1.4 Polyurethane Coating

2.1.5 Polyolefin Coating

2.1.6 Tape Coating

2.1.7 Bitumen Coating

2.1.8 Coal-Tar Enamel Coating

2.1.9 Concrete Weighted Coating

5:External concrete coating.

2.1.10 Marine Coating

2.1.11 Other specification

2.2. Lining

2.2.1 Epoxy Lining

2.2.2 Bitumen Lining

2.2.3 Cement Mortar Lining

2.2.4 Shop Cement Lined Piping

Pipe Coating Products

Three Layer Polyethylene (3LPE)

To improve anticorrosion performance and adhesion, an additional layer of epoxy primer is sprayed onto pipe surfaces prior to the adhesive layer and Polyethylene top layer application. Three Layer Polyethylene is suitable for service temperatures from 60°C to 80°C (85°C peaks). Typical coating thickness is from 1-2 mm to 3-5 mm.

Three Layer Polypropylene (3LPP)

If a wider service temperature range and high stiffness is required, adhesive and top layers, applied over primer layer, are based on polypropylene instead of polyethylene. Three Layer Polypropylene is suitable for service temperatures up to 135 °C (140°C peaks). Typical coating thickness is from 1-2 mm to 3-5 mm.

Three Layer Polypropylene and Polyethylene

Three Layer applications involve a thermoplastic coating applied to steel pipelines as a form of anticorrosion protection. This mechanical resistance is appropriate when the risk of particularly severe coating damages exist. The Three Layer process involved several steps. First, the pipe surface is blast cleaned to remove any external residue from the mill or storage. It is then heated and sprayed with a Fusion Bond Epoxy (FBE) primer followed by the application of an adhesive copolymer and polyolefin polymers that are wrap extruded, one over the other.

Field applied products

Advantage of ERW pipe

The alloy content of the coil is often lower than similar grades of steel plate, improving the weldability of the spiral welded pipe. Due to the rolling direction of spiral welded pipe coil is not perpendicular to the pipe axis direction, the crack resistance of the spiral welded pipe materials.

Need to inquire about our products? Fill out the form below and our staff will be in touch!

Q: How long is your delivery time?

A: The delivery time of customized products is generally 25 35 days, and non customized products are generally shipped within 24 hours after payment.

Q: Do you provide samples? Is it free?

A: If the value of the sample is low, we will provide it for free, but the freight needs to be paid by the customer. But for some high value samples, we need to charge a fee.

Q: What are your payment terms?

A: T/T 30% as the deposit,The balance payment is paid in full before shipment

Q: What is the packaging and transportation form?

A: Non steaming wooden box and iron frame packaging. Special packaging is available according to customer needs. The transportation is mainly by sea.

Q: What is your minimum order quantity?

A: There is no minimum order quantity requirement. Customized products are tailor made according to the drawings provided by the customer.