Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

The EFW pipe divison consists of a JCO forming press, helical / spiral mill, inside and outside welding system, heat treatment furnace and testing facilities.

The EFW pipe divison consists of a JCO forming press, helical / spiral mill, inside and outside welding system, heat treatment furnace and testing facilities. Welding process employed is gtaw for root-pass and saw/tig for final pass with suitable filler wires as prescribed by aws specifications and asme boiler and pressure vessel code, section-ix. These facilities are capable of manufacturing austenitic and various duplex grades.

Sunny Steel has been supplying EFW Electric Fusion Welded Pipe for many years.

We supply EFW electric fusion welded pipe to the folowing industries on a global scale:

For pipes or tubes size 4 inch (10.2mm) OD and below, strip is fed into a set of forming rolls which consists of horizontal and vertical rollers so placed as to gradually from the flat strip in to a tube which is then allowed to pass the welding electrodes. The electrodes are copper disks connected to the secondary of a revolving transformer assembly.

The copper disk electrodes make contact on each side of the seam and temperature is raised to the welding point. Outside flash is removed by a cutting tool as the tube leaves the electrodes, inside flash is removed either by an air hammer or by passing a mandnel through the welded tube after the tube has been cooled.

This is termed as Electric Resistance welded or ERW tube/pipe. If this ERW is being drawn further to get desired size of tubes or pipes, in cold condition is called as Cold Drawn welded or CDW.

This process is used for pipes from 24″ to 36″ i.e 610mm to 914mm OD. Flat plate is first pressed into U and later O shape.

The O shape is placed in an automatic welder and backed up on the inside by a water cooled copper shoe. Two electrodes in close proximity and used. The electrodes are not in actual contact with the pipe. The current passes from on electrode through a granular flux and across the gap in the pipe to the second electrode. The high temperature of the arc heats the edges of the plate, a welding rod placed just over the seam is thereby melted and metal is deposited in the groove.

After the outside weld has been made, the pipe is conveyed to an inside welder where a similar operation is carried on, except that no backup shoe is need.

welding member combination is applying pressure through the electrodes, the use of current through the joint area of the contact surface and the adjacent heat generating resistance welding process method, Also known as contact welding. It has excellent toughness and dynamic load strength, welding deformation.

Commonly used spot welding, seam welding and butt three.

In the field of fluid medium transmission, polyethylene (PE) pipe is wide attention in recent years and has been the rapid development of new pressure structure.

Compared with the traditional metal pipe, polyethylene piping systems for light weight, strength and specific rigidity, durability, corrosion resistance, insulation, composite capacity and resistance to fracture. Easy to manufacture and installation, and low cost, the typical service life of up to the metal several times and can save a lot of energy production and use. It is used in the field of urban water supply and drainage and gas transportation and distribution system, agricultural irrigation and drainage systems, factories, mines ventilation system and mud, ore pipeline transportation.

Polyethylene piping systems for manufacturing and laying pipe connection between the impact of an important part of its structural integrity and lasting strength. Since polyethylene molecular chain by a methylene group, and having a high degree of symmetry. Determines its polarity is low, so the connection of the polyethylene pipe can not be used solvent bonding method using only mechanical connection or welding. Practice shows that the welding is a high-quality, high-efficiency plastic pipe connection technology. More mature welding techniques include socket weld, butt welding, fusion welded.

Heating wire which are fused welding molten weld has been the development and promotion of the construction is simple, portable field devices, welding speed, and soon. The basic principle is the high resistance of the wire pre-embedded in the plastic casing wall. Plug, Walter current, electric heating wire to make it around the plastic Division Heating and melting into each other, to form a weld cooling. Its main disadvantage is: (1) when the plastic melts and a small amount of current, closely-spaced heating wire are overlapped with each other to cause a short circuit failure often makes welding; (2) the high cost, the heating wire embedded within the plastic injection molding process and mold complex, will inevitably lead to the high production costs of the welded joints; (3) Upon completion of the welding, electric wire remaining in the weld affect performance, on the one hand, on the other hand, cause unnecessary alloy material waste.

Prepared using the carbon felt polyethylene laminated composite conductive composites as fusion welded materials is feasible during power-up, the resistance of the composite rate of change is very small, can be heated to the melting temperature of polyethylene. Composite molding process parameters temperature of 160 ° C, time 10 min, pressure 10 MPa, the resistance of the composite control in a 100 W. Factors affect the weld strength of the fused heating power, heating time, they impact on the weld strength is mainly attributed to the influence of the temperature of the heating layer, when the temperature of the heating layer is controlled within the range of 140 220 ° C, to obtain satisfactory weld strength. Therefore, the type of input power, it is possible to select an appropriate heating time to achieve the desired welding effect. Electrofusion welding, the presence of a heat affected zone in the vicinity of the heating layer in the melted layer and the heat-affected zone, the degree of crystallinity of the polyethylene, the crystal size will be changed, so that the properties of the material affected.

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

|---|---|---|---|

| Electric-Resistance-Welded Steel Pipes | ASTM A135 | 42.2-114.3 x 2.11-2.63 | A |

| Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes | ASTM A178 | 42.2-114.3 x 2.11-2.63 | A, C,D |

| ERW and Hot-dip Galvanized Steel Pipes | ASTM A53 | 21.3-273 x 2.11-12.7 | A, B |

| Pipes for Piling Usage | ASTM A252 | 219.1-508 x 3.6-12.7 | Gr2, Gr3 |

| Tubes for General Structural Purpose | ASTM A500 | 21.3-273 x 2.11-12.7 | Carbon Steel |

| Square Pipes for General Structural Purpose | ASTM A500 | 25 x 25-160 x 160 x 1.2-8.0 | Carbon Steel |

| Mechanical tubing | ASTM A513 | 21.3-273 x 2.11-12.7 | carbon and alloy steel |

| Screwed and Socketed Steel Tubes | BS 1387 | 21.4-113.9 x 2-3.6 | Carbon Steel |

| Scaffolding Pipes | EN 39 | 48.3 x 3.2-4 | Carbon Steel |

| Carbon Steel Tubes for General Structure Purpose | JIS G3444 | 21.7-216.3 x 2.0-6.0 | Carbon Steel |

| Carbon Steel Tubes for Machine Structure Purpose | JIS G3445 | 15-76 x 0.7-3.0 | STKM11A, STKM13A |

| Carbon Steel Pipes for Ordinary Piping | JIS G3452 | 21.9-216.3 x 2.8-5.8 | Carbon Steel |

| Carbon Steel Pipes for Pressure Service | JIS G3454 | 21.7-216.3 x 2.8-7.1 | Carbon Steel |

| Carbon Steel Rigid Steel Conduits | JIS G8305 | 21-113.4 x 1.2-3.5 | G16-G104, C19-C75, E19-E75 |

| Carbon Steel Rectangular Pipes for General Structure | JIS G3466 | 16 x 16-150 x 150 x 0.7-6 | Carbon Steel |

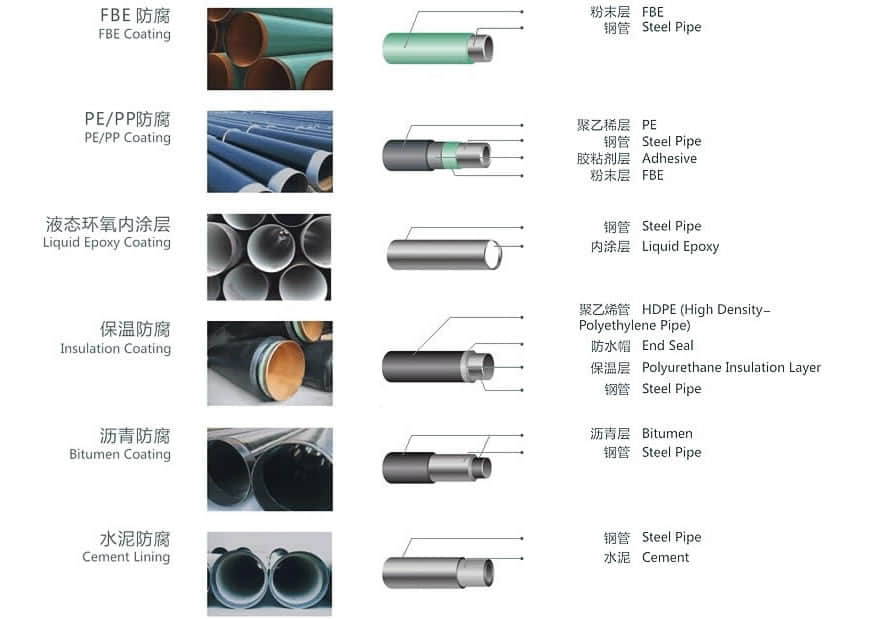

Pipeline coating is the most consistent and successful solution for protecting ERW pipes from corrosion, from moisture, other harmful chemicals.

Anti-corrosion steel pipe is processed through the preservation process, which can effectively prevent or slow down the process in the transport and use of chemical or electrochemical corrosion reaction of steel pipe.

Therefore pipe anti-corrosion layer is an important barrier to prevent soil erosion. A well-known foreign scholar put forward” 3PE france protective layer”, so far, anti-corrosion methods is widely used.

Coated pipes offer high resistance to corrosion on pipes and provide many benefits such as:

1. Increased Flow Capacity – A coating on pipes helps provide a smoother surface thus improving gas and liquid flow within pipes.

2. Reduced Cost – The pipeline coating increases the pipes durability so they can be deployed with minimum maintenance cost even in the harshest environments.

3. Lower energy usage – Various studies have shown that pipelines that are internally coated use less energy for pumping and compression of products through pipes. This helps in increased saving over time.

4. Clean delivery of products – The inhibitors used for the protection products can also be minimized by the use of coated pipes for delivery of products.

Thus, coating of pipelines can help you in reducing your maintenance cost and at the same time providing a corrosion free reliable protection.

The basic principles of urban gas pipeline coating selection:

2.1.External Coating

2.1.1 External Epoxy Coating

2.1.2 Polyethylene Coating

2.1.3 Polypropylene Coating

2.1.4 Polyurethane Coating

2.1.5 Polyolefin Coating

2.1.6 Tape Coating

2.1.7 Bitumen Coating

2.1.8 Coal-Tar Enamel Coating

2.1.9 Concrete Weighted Coating

5:External concrete coating.

2.1.10 Marine Coating

2.1.11 Other specification

2.2. Lining

2.2.1 Epoxy Lining

2.2.2 Bitumen Lining

2.2.3 Cement Mortar Lining

2.2.4 Shop Cement Lined Piping

Pipe Coating Products

Three Layer Polyethylene (3LPE)

To improve anticorrosion performance and adhesion, an additional layer of epoxy primer is sprayed onto pipe surfaces prior to the adhesive layer and Polyethylene top layer application. Three Layer Polyethylene is suitable for service temperatures from 60°C to 80°C (85°C peaks). Typical coating thickness is from 1-2 mm to 3-5 mm.

Three Layer Polypropylene (3LPP)

If a wider service temperature range and high stiffness is required, adhesive and top layers, applied over primer layer, are based on polypropylene instead of polyethylene. Three Layer Polypropylene is suitable for service temperatures up to 135 °C (140°C peaks). Typical coating thickness is from 1-2 mm to 3-5 mm.

Three Layer Polypropylene and Polyethylene

Three Layer applications involve a thermoplastic coating applied to steel pipelines as a form of anticorrosion protection. This mechanical resistance is appropriate when the risk of particularly severe coating damages exist. The Three Layer process involved several steps. First, the pipe surface is blast cleaned to remove any external residue from the mill or storage. It is then heated and sprayed with a Fusion Bond Epoxy (FBE) primer followed by the application of an adhesive copolymer and polyolefin polymers that are wrap extruded, one over the other.

Field applied products

Advantage of ERW pipe

The alloy content of the coil is often lower than similar grades of steel plate, improving the weldability of the spiral welded pipe. Due to the rolling direction of spiral welded pipe coil is not perpendicular to the pipe axis direction, the crack resistance of the spiral welded pipe materials.

Need to inquire about our products? Fill out the form below and our staff will be in touch!

Q: How long is your delivery time?

A: The delivery time of customized products is generally 25 35 days, and non customized products are generally shipped within 24 hours after payment.

Q: Do you provide samples? Is it free?

A: If the value of the sample is low, we will provide it for free, but the freight needs to be paid by the customer. But for some high value samples, we need to charge a fee.

Q: What are your payment terms?

A: T/T 30% as the deposit,The balance payment is paid in full before shipment

Q: What is the packaging and transportation form?

A: Non steaming wooden box and iron frame packaging. Special packaging is available according to customer needs. The transportation is mainly by sea.

Q: What is your minimum order quantity?

A: There is no minimum order quantity requirement. Customized products are tailor made according to the drawings provided by the customer.