Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

The mill adopts continuous axis contorting J-C-O(J-ing, C-ing and O-ing)process with characteristics of high forming accuracy and efficiency as well as balanced distribution of forming stress.

SAW is normally operated in the automatic or mechanized mode, however, semi-automatic (hand-held) SAW guns with pressurized or gravity flux feed delivery are available.

Submerged arc welding (SAW) is a common arc welding process.

The process is normally limited to the flat or horizontal-fillet welding positions (although horizontal groove position welds have been done with a special arrangement to support the flux).

SAW pipe is made of hot rolled coiled steel by automatic submerged arc weld under normal atmospheric temperature. All the pipes are produced according to API Spec 5L, GB/T9711.1, GB/T9711.2, ASTM A252-89 standard. These pipes mainly used in petroleum and natural gas industry to transport flammable and non-flammable liquid and steel construction.

SAW means submerged arc weld ,it can be classified into LSAW and SSAW

Size range:

The pipes are supplied according to appropriate standards as well as customer specifications in a large variety of steel grades and dimensions.

Execute Standard:

Specific requirements on execution, tolerances, lengths, and mechanical & chemical properties are offered on request.

Material:

Pipe Coating: HDPE/ 3PE/ 3PP/ Pipe cement mortar lining

In addition to above specification, the pipes can be produced according to customer’s requirements.

Mainly usage:

Spiral welded steel pipes are widely used in Oil, Natural Gas, Water and other flammable & nonflammable liquid conveyance and distribution pipelines, steel structures for construction and other general purposes by means of their wide size range.

In single seam SAW pipe, wedding is done with the help of submerged arc welding process. In this method, a welding arc is submerged in welding flux. A Continues solid filler wire is fed from the outside. The pipe is welded first inside and then from the outside.

In the case of double seam saw pipe first two halves are joined by tack weld which is called fit-up. Double seam saw pipe is havening a two weld seam opposite to each other. Both the seams are welded from inside and outside of the pipe. In the case of high thickness pipe, multiple pass welding is done.

In a spiral saw pipe, steel plate from the de-coiler is formed in a spiral loop. This spiral loop is then welded from inside and outside of the pipe. Because of the method of manufacture, a wide variety of diameters can be produced. Spiral saw pipes are used for low-pressure services.

Whereas straight saw pipes are used for medium to high-pressure services. Spiral saw pipes are less costly compared to straight saw pipe.

Once the welding is completed heat treatment is carried out on the weld or on the full body of pipe, this depends on the thickness of pipes. Weld seams are also subjected to various non-destructive testing such as RT & UT to ensure the soundness of the weld material.

Once all NDT is completed pipes are hydro tested to ensure strength and ability to remain leak proof under pressure. In the last stage of inspection, the pipe is checked visually and dimensionally by competent inspection engineer. He will ensure that pipe is meeting the code, standard, and specification requirements. Once the Inspection engineer cleared the pipe, it will mark as per the standard requirements & send for the packaging.

As ERW steel pipe and SAW steel pipe in the pipe during forming, welding and process is different, so that two kinds of steel pipe in the performance there are some differences.

ERW steel pipe surface quality is superior to spiral submerged arc welded pipe, ERW steel pipe surface is smooth, smooth, beautiful, SAW steel pipe internal and external weld reinforcement.

ERW steel pipe weld defect types is less than the saw steel pipe. Saw steel pipe with solvent deposited, more types of defects, in addition to volume defects, there are wire-line trap. ERW steel pipe weld defects only wire-line and straight welds, the inspection process easy to follow, and the defects in the maximum reflection at, once the lack of implicit, ultrasonic reflecting the strong, easy to detect.

ERW steel pipe related to saw steel pipe in residual stress ratio is low. Since ERW pipe deformation in the deformation process more fully, coupled subsequent sizing flat oval, elliptical vertical changes and necking, making ERW pipe residual stress becomes smaller. Physical testing showed that the same specifications, the same material ERW pipe after incision along the axis, the axial and transverse incisions smaller displacement than the spiral submerged arc welded pipe.

ERW Pipe overall performance of the same, when the pipe becomes defective, steel scrap judgment, allow welding. SAW steel pipe allowed, and pipe welding performance and overall performance is inconsistent, welding place prone to stress corrosion cracking. Experiments show that stress corrosion fatigue test ERW pipe spiral submerged arc welded pipe length than life.

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

|---|---|---|---|

| Electric-Resistance-Welded Steel Pipes | ASTM A135 | 42.2-114.3 x 2.11-2.63 | A |

| Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes | ASTM A178 | 42.2-114.3 x 2.11-2.63 | A, C,D |

| ERW and Hot-dip Galvanized Steel Pipes | ASTM A53 | 21.3-273 x 2.11-12.7 | A, B |

| Pipes for Piling Usage | ASTM A252 | 219.1-508 x 3.6-12.7 | Gr2, Gr3 |

| Tubes for General Structural Purpose | ASTM A500 | 21.3-273 x 2.11-12.7 | Carbon Steel |

| Square Pipes for General Structural Purpose | ASTM A500 | 25 x 25-160 x 160 x 1.2-8.0 | Carbon Steel |

| Mechanical tubing | ASTM A513 | 21.3-273 x 2.11-12.7 | carbon and alloy steel |

| Screwed and Socketed Steel Tubes | BS 1387 | 21.4-113.9 x 2-3.6 | Carbon Steel |

| Scaffolding Pipes | EN 39 | 48.3 x 3.2-4 | Carbon Steel |

| Carbon Steel Tubes for General Structure Purpose | JIS G3444 | 21.7-216.3 x 2.0-6.0 | Carbon Steel |

| Carbon Steel Tubes for Machine Structure Purpose | JIS G3445 | 15-76 x 0.7-3.0 | STKM11A, STKM13A |

| Carbon Steel Pipes for Ordinary Piping | JIS G3452 | 21.9-216.3 x 2.8-5.8 | Carbon Steel |

| Carbon Steel Pipes for Pressure Service | JIS G3454 | 21.7-216.3 x 2.8-7.1 | Carbon Steel |

| Carbon Steel Rigid Steel Conduits | JIS G8305 | 21-113.4 x 1.2-3.5 | G16-G104, C19-C75, E19-E75 |

| Carbon Steel Rectangular Pipes for General Structure | JIS G3466 | 16 x 16-150 x 150 x 0.7-6 | Carbon Steel |

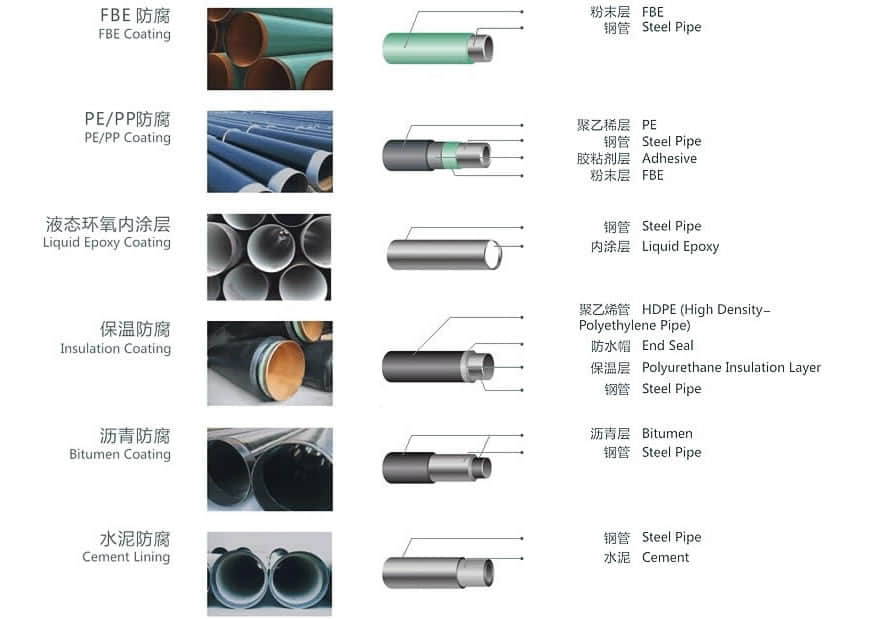

Pipeline coating is the most consistent and successful solution for protecting ERW pipes from corrosion, from moisture, other harmful chemicals.

Anti-corrosion steel pipe is processed through the preservation process, which can effectively prevent or slow down the process in the transport and use of chemical or electrochemical corrosion reaction of steel pipe.

Therefore pipe anti-corrosion layer is an important barrier to prevent soil erosion. A well-known foreign scholar put forward” 3PE france protective layer”, so far, anti-corrosion methods is widely used.

Coated pipes offer high resistance to corrosion on pipes and provide many benefits such as:

1. Increased Flow Capacity – A coating on pipes helps provide a smoother surface thus improving gas and liquid flow within pipes.

2. Reduced Cost – The pipeline coating increases the pipes durability so they can be deployed with minimum maintenance cost even in the harshest environments.

3. Lower energy usage – Various studies have shown that pipelines that are internally coated use less energy for pumping and compression of products through pipes. This helps in increased saving over time.

4. Clean delivery of products – The inhibitors used for the protection products can also be minimized by the use of coated pipes for delivery of products.

Thus, coating of pipelines can help you in reducing your maintenance cost and at the same time providing a corrosion free reliable protection.

The basic principles of urban gas pipeline coating selection:

2.1.External Coating

2.1.1 External Epoxy Coating

2.1.2 Polyethylene Coating

2.1.3 Polypropylene Coating

2.1.4 Polyurethane Coating

2.1.5 Polyolefin Coating

2.1.6 Tape Coating

2.1.7 Bitumen Coating

2.1.8 Coal-Tar Enamel Coating

2.1.9 Concrete Weighted Coating

5:External concrete coating.

2.1.10 Marine Coating

2.1.11 Other specification

2.2. Lining

2.2.1 Epoxy Lining

2.2.2 Bitumen Lining

2.2.3 Cement Mortar Lining

2.2.4 Shop Cement Lined Piping

Pipe Coating Products

Three Layer Polyethylene (3LPE)

To improve anticorrosion performance and adhesion, an additional layer of epoxy primer is sprayed onto pipe surfaces prior to the adhesive layer and Polyethylene top layer application. Three Layer Polyethylene is suitable for service temperatures from 60°C to 80°C (85°C peaks). Typical coating thickness is from 1-2 mm to 3-5 mm.

Three Layer Polypropylene (3LPP)

If a wider service temperature range and high stiffness is required, adhesive and top layers, applied over primer layer, are based on polypropylene instead of polyethylene. Three Layer Polypropylene is suitable for service temperatures up to 135 °C (140°C peaks). Typical coating thickness is from 1-2 mm to 3-5 mm.

Three Layer Polypropylene and Polyethylene

Three Layer applications involve a thermoplastic coating applied to steel pipelines as a form of anticorrosion protection. This mechanical resistance is appropriate when the risk of particularly severe coating damages exist. The Three Layer process involved several steps. First, the pipe surface is blast cleaned to remove any external residue from the mill or storage. It is then heated and sprayed with a Fusion Bond Epoxy (FBE) primer followed by the application of an adhesive copolymer and polyolefin polymers that are wrap extruded, one over the other.

Field applied products

Advantage of ERW pipe

The alloy content of the coil is often lower than similar grades of steel plate, improving the weldability of the spiral welded pipe. Due to the rolling direction of spiral welded pipe coil is not perpendicular to the pipe axis direction, the crack resistance of the spiral welded pipe materials.

Need to inquire about our products? Fill out the form below and our staff will be in touch!

Q: How long is your delivery time?

A: The delivery time of customized products is generally 25 35 days, and non customized products are generally shipped within 24 hours after payment.

Q: Do you provide samples? Is it free?

A: If the value of the sample is low, we will provide it for free, but the freight needs to be paid by the customer. But for some high value samples, we need to charge a fee.

Q: What are your payment terms?

A: T/T 30% as the deposit,The balance payment is paid in full before shipment

Q: What is the packaging and transportation form?

A: Non steaming wooden box and iron frame packaging. Special packaging is available according to customer needs. The transportation is mainly by sea.

Q: What is your minimum order quantity?

A: There is no minimum order quantity requirement. Customized products are tailor made according to the drawings provided by the customer.