Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

ASTM A519 carbon and alloy steel mechanical tubing used in the mechanical tubing may be cast in ingots or may be strand cast.

ASTM A519 carbon and alloy steel mechanical tubing used in the mechanical tubing may be cast in ingots or may be strand cast.

The steel used in the mechanical tubing may be cast in ingots or may be strand cast. When steel of different grades is sequentially strand cast, identification of the resultant transition material is required. The seamless tubing is a tubular product made without a welded seam. It is usually manufactured by hot working steel, and if necessary, by subsequently cold finishing the hot-worked tubular product to produce the desired shape, dimensions and properties.

The tubes shall be furnished in the following shapes: round, square, rectangular and special sections. Heat analysis shall be made to determine the percentages of the elements specified. If secondary melting processes are used, the heat analysis shall be obtained from one remelted ingot or the product of one remelted ingot of each primary melt. The tubing shall be coated with a film of oil before shaping to retard rust when specified This abstract is a brief summary of the referenced standard. It is informational only and not an official part of the standard; the full text of the standard itself must be referred to for its use and application. ASTM does not give any warranty express or implied or make any representation that the contents of this abstract are accurate, complete or up to date.

Size range(mm):

| Grade Designation | C | Mn | P≤ | S≤ | Si | Cr | Mo |

|---|---|---|---|---|---|---|---|

| 1008 | ≤0.10 | 0.30-0.50 | 0.04 | 0.05 | - | - | - |

| 1010 | 0.08-0.13 | 0.30-0.60 | 0.04 | 0.05 | - | - | - |

| 1018 | 0.15-0.20 | 0.60-0.90 | 0.04 | 0.05 | - | - | - |

| 1020 | 0.18-0.23 | 0.30-0.60 | 0.04 | 0.05 | - | - | - |

| 1025 | 0.22-0.28 | 0.30-0.60 | 0.04 | 0.05 | - | - | - |

| 1026 | 0.22-0.28 | 0.60-0.90 | 0.04 | 0.05 | - | - | - |

| 4130 | 0.28-0.33 | 0.40-0.60 | 0.04 | 0.05 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.75-1.00 | 0.04 | 0.05 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

| Grade | Condition | MPa Tenslle Point | Yield Point | Elongation |

|---|---|---|---|---|

| 1020 | CW | ≥414 | ≥483 | ≥5% |

| SR | ≥345 | ≥448 | ≥10% | |

| A | ≥193 | ≥331 | ≥30% | |

| N | ≥234 | ≥379 | ≥22% | |

| 1025 | CW | ≥448 | ≥517 | ≥5% |

| SR | ≥379 | ≥483 | ≥8% | |

| A | ≥207 | ≥365 | ≥25% | |

| N | ≥248 | ≥379 | ≥22% | |

| 4130 | SR | ≥586 | ≥724 | ≥10% |

| A | ≥379 | ≥517 | ≥30% | |

| N | ≥414 | ≥621 | ≥20% | |

| 4140 | SR | ≥689 | ≥855 | ≥10% |

| A | ≥414 | ≥552 | ≥25% | |

| N | ≥621 | ≥855 | ≥20% |

| JIS | ASTM | BS | DIN | NF | ISO | Index Number | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard Number | Grade | Tupe | Standard Number | Grade | Tupe | Standard Number | Grade | Tupe | Standard Number | Grade | Tupe | Standard Number | Grade | Tupe | Standard Number | Grade | Tupe | |

| G3445 | STKM11A | C | ASTM A512 | MT1010 | C | 1717 | ERWC1 | C | 2391 | St30Si | C | 3304 | R28 | C | C017 | |||

| ASTM A513 | MT1010 | C | St30A1 | C | 3305 | " | C | |||||||||||

| 2393 | St28 | C | 3306 | " | C | |||||||||||||

| RSt28 | C | |||||||||||||||||

| 2394 | St28 | C | ||||||||||||||||

| USt28 | C | |||||||||||||||||

| RSt28 | C | |||||||||||||||||

| STKM12A | C | ASTM A512 | MT1015 | C | 1717 | ERWC2 | C | 2391 | St37-2 | 3304 | R33 | C | ||||||

| ASTM A513 | MT1015 | C | 6323 | HFS3 | C | RSt37-2 | 3305 | " | " | |||||||||

| STKM12B | C | ASTM A512 | MT1015 | C | 2394 | St37-2 | 3306 | " | " | |||||||||

| ASTM A513 | MT1015 | C | Ust38-2 | |||||||||||||||

| ASTM A519 | MT1015 | C | RSt-2 | |||||||||||||||

| STKM12C | C | 1717 | CEWC2 | C | A49-322 | TU37b | C | |||||||||||

| " | CFSC3 | C | A49-327 | TU37b | C | |||||||||||||

| 6323 | CFS3 | C | ||||||||||||||||

| " | CFS3A | C | ||||||||||||||||

| STKM13A | C | ASTM A312 | MT1020 | C | 1717 | ERWC3 | C | 2391 | St45 | C | A49-324 | TU37b | C | 2937 | TS4 | C | ||

| ASTM A513 | MT1020 | C | 2393 | St44-2 | C | A49-330 | TU37b | C | 3304 | R37 | " | |||||||

| 2394 | St44-2 | C | A49-343 | TU38b | C | 3305 | " | " | ||||||||||

| STKM13B | C | ASTM A513 | MT1020 | C | 3306 | " | " | |||||||||||

| STKM13C | C | 1717 | CEWC3 | C | ||||||||||||||

| " | CFSC4 | C | ||||||||||||||||

| 6323 | CFS4 | C | ||||||||||||||||

| STKM14A | C | ASTM A513 | MT1020 | C | 6323 | HFS4 | C | 2937 | TS9 | C | ||||||||

| 3304 | R42 | " | ||||||||||||||||

| STKM14B | C | 6323 | HFS5 | C | 3305 | R42 | C | |||||||||||

| STMK14C | C | 3306 | " | " | ||||||||||||||

| STKM15A | C | ASTM A513 | 1030 | C | ||||||||||||||

| ASTM A519 | 1030 | C | ||||||||||||||||

| STKM15C | ||||||||||||||||||

| STKM16A | C | ASTM A519 | 1040 | C | A49-311 | TUXC35 | C | |||||||||||

| A49-312 | TUXC35 | C | ||||||||||||||||

| STKM16C | C | |||||||||||||||||

| STKM17A | C | ASTM A519 | 1050 | C | 6323 | HFS8 | C | |||||||||||

| STKM17C | C | 6323 | CFS8 | C | ||||||||||||||

| STKM18A | C | ASTM A519 | 1518 | C | 1717 | ERWC5 | C | A49-310 | TU52b | C | ||||||||

| A49-311 | TU52b | C | ||||||||||||||||

| A49-312 | TU52b | C | ||||||||||||||||

| STKM18B | C | A49-321 | TU52b | C | ||||||||||||||

| A49-323 | TU52b | C | ||||||||||||||||

| A49-326 | TU52b | C | ||||||||||||||||

| STKM18C | C | A49-330 | TU52b | C | ||||||||||||||

| A49-341 | TS42a | C | ||||||||||||||||

| " | TS47a | C | ||||||||||||||||

| A49-343 | TS18M5 | C | ||||||||||||||||

| STKM19A | C | ASTM A519 | 1524 | C | 2391 | ST52 | C | 2937 | TS18 | C | ||||||||

| 2393 | ST52-3 | C | 2938 | Gr.1 | C | |||||||||||||

| 2394 | ST52-3 | C | 3304 | R50 | C | |||||||||||||

| 3305 | R50 | C | ||||||||||||||||

| 3306 | R50 | C | ||||||||||||||||

| STKM20A | C | |||||||||||||||||

| G3441 | SCr420TK | Cr | C018 | |||||||||||||||

| SCM415TK | CrMo | |||||||||||||||||

| SCM418TK | CrMo | 6323 | CFS10 | CrMo | ||||||||||||||

| SCM420TK | CrMo | ASTM A519 | 5120 | CrMo | ||||||||||||||

| SCM430TK | CrMo | ASTM A519 | 4130 | CrMo | ||||||||||||||

| SCM435TK | CrMo | ASTM A519 | 4135 | CrMo | ||||||||||||||

| SCM440TK | CrMo | ASTM A519 | 4140 | CrMo | 6323 | CFS10 | CrMo | |||||||||||

The production of our seamless pipes is tightly regulated and all of the pipes we stock have been fully tested to international standards to ensure we only supply the highest quality products.

| Product name | Executive standard | Dimension (mm) | Steel code/ Steel grade |

|---|---|---|---|

| Black and Hot-dipped Zinc-coated Steel Pipes Seamless | ASTM A53 | 0.3-1200 x 1.0-150 | GR.A, GR.B, GR.C |

| Seamless Carbon Steel for High Temperature Service | ASTM A106 | 10.3-1200 x 1.0-150 | GR.B, GR.C |

| Seamless Cold-drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes | ASTM A179 | 10.3-426 x 1.0-36 | Low Carbon Steel |

| Seamless Carbon Steel Boiler Tubes for High Pressure | ASTM A192 | 10.3-426 x 1.0-36 | Low Carbon Steel |

| Seamless Cold-drawn Intermediate Alloy Steel Heat-exchanger and Condenser Tubes | ASTM A199 | 10.3-426 x 1.0-36 | T5, T22 |

| Seamless Medium-carbon Steel Boiler and Superheater Tubes | ASTM A210 | 10.3-426 x 1.0-36 | A1, C |

| Seamless Ferritic and Austenitic Alloy Steel Boiler, Superheater and Heat-exchanger Tubes | ASTM A213 | 10.3-426 x 1.0-36 | T5, T5b, T9 , T11, T22 ,T91 |

| Seamless Carbon and Alloy Steel for Mechanical Tubing | ASTM A333 | 1/4"-42" x SCH20-XXS | Grade1 Gr. 3,Gr..6, Gr.8 , Gr. 9 |

| Seamless Cold-drawn Carbon Steel Feedwater Heater Tubes | ASTM A556 | 10.3-426 x 1.0-36 | A2, B2 |

| Round and shaped steel cold formed welded and seamless carbon steel structural pipe. | ASTM A500 | OD :10.3-820 x 0.8- 75 | Grade A, B, C, D |

| Carbon and alloy steel mechanical tubing, either hot-finished or cold-finished | ASTM A519 | 10.3-426 x 1.0-36 | 1020, 1025, 4130, 4140 |

| For seamless ferritic alloy-steel pipe for high-temperature service | ASTM A335 | 1/4"-42" x SCH20-XXS | A/SA 335 P1, P2, P11, P12, P15, P22, P91, P92, P122 |

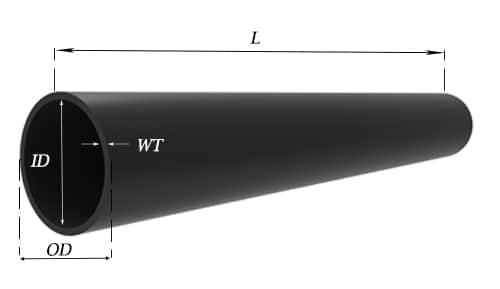

Geometrical inspection of steel pipes The outer diameter, wall thickness, bending and length of the steel pipe can be inspected on the inspection table with an outer caliper, a micrometer and a bending ruler, and a length tape measure.

Take seamless steel pipe as an example, there are some tolerances that affect quality. Noting this, and you will get a better pipe.

Weight tolerance

For pipe NPS 12 (DN300, 323.8mm) and under, the weight shall vary within -3.5% / +10%.

For pipe over NPS 12 (DN300, 323.8mm), the weight shall vary within -5% / +10%.

Pipe of NPS 4 (DN100, 114.3mm) and smaller may be weighed in convenient lots; pipe in sizes larger than NPS 4 shall be weighed separately.

Quantity tolerance

Normally mills take -10% to +10% tolerance, but TPMCSTEEL keeps ±3% variation.

Length tolerance

For Seamless pipe& tube, if definite cut lengths are ordered, the length shall vary within -0mm / +6mm.

| Pipe types | Pipe Szie(mm) | Tolerances | |

|---|---|---|---|

| Hot rolled | OD | <50 | ±0.50mm |

| ≥50 | ±1% | ||

| WT | <4 | ±12.5% | |

| ≥4-20 | +15%, -12.5% | ||

| >20 | ±12.5% | ||

| Cold drawn | OD | 6-10 | ±0.20mm |

| 10-30 | ±0.40mm | ||

| 30-50 | ±0.45 | ||

| >50 | ±1% | ||

| WT | <1 | ±0.15mm | |

| >1-3 | + 15%, – 10% | ||

| >3 | + 12.5%, – 10% | ||

| Standard | Hot finished seamless tube | Cold flnished seamless tube | ||

|---|---|---|---|---|

| Out diameter (mm) | Tolerance | Out diameter (mm) | Tolerance | |

| EN10216-1 | ≤100 | +/-0.75% (min.+/-0.5mm) | All | +/-0.5% |

| EN10216-2 | (min. +/-0.30mm) | |||

| DIN17175 | >100 | +/-0.90% | ||

| GB/T 3087 | ≤460 | +/-0.75% (min.+/-0.5mm) | 10-30 | +/-0.40mm |

| >30-50 | +/-0.45mm | |||

| >50 | +/-1.0% | |||

| GB/T 5310 GB/T 9948 GB/T 6479 | <57 | +/-0.40mm | ≤30 | +/-0.20mm |

| 57-325 | +/-0.75% | >30-50 | +/-0.30mm | |

| >325-460 | +1%,-2mm | >50 | +/-0.8% | |

| ASME SA-179M ASME SA-192M ASME SA-209M ASME SA-210M ASME SA-213M JIS G 3461 JIS G 3461 | ≤101.6 | +0.4, -0.8mm | <25.4 | +/-0.10mm |

| >25.4-38.1 | +/-0.15mm | |||

| >38.1-50.8 | +/-0.20mm | |||

| 101.6-190.5 | +0.4, -1.2mm | >50.8-63.5 | +/-0.25mm | |

| >63.5-76.2 | +/-0.30mm | |||

| >76.2 | +/-0.38mm | |||

| ASME SA106 ASME SA335 | ≤48.3 | +/-0.40mm | ≤48.3 | +/-0.40mm |

| 48.3-114.3 | +/-0.79mm | |||

| 114.4-219.1 | +1.59, -0.79mm | |||

| 219.2-323.9 | +2.38, -0.79mm | >48.3 | +/-0.79mm | |

| >324 | +/-1.0% | |||

| Standard | Hot finished seamless tube | Cold flnished seamless tube | ||||

|---|---|---|---|---|---|---|

| DIN17175 | Out diameter OD(mm) | Wall thickness T(mm) | Tolerance | Out diameter (mm) | Wall Thickness T(mm) | Tolerance |

| ≤130 | S≤2Sn | +15%, -10% | -- | All | +/-10% (min. +/-0.2mm) |

|

2Sn| +12.5%, -10% |

| |||||

| S>4Sn | +-/9% | |||||

| >130 | S≤0.05da | +17.5%, -12.5% | ||||

0.05da| +/-12.5% |

| |||||

| S>0.11da | +/-10% | |||||

| EN 10216-1 EN 10216-2 | ≤219.1 | - | +/-12.5% (min.+/-0.4mm) |

|||

| -- | T/D≤0.025 | +/-20% | ||||

0.025| +/-15% |

| |||||

0.05| +/-12.5% |

| |||||

0.1| +/-10% |

| |||||

| GB/T 3087 | -- | ≤20 | +15%,-12.5% (min.+0.45, -0.35mm) | -- | 1.0-3.0 | +15%, -10% |

| >20 | +/-12.5% | -- | >3 | +12.5%, -10% | ||

| GB/T 5310 GB/T 9948 GB/T 6479 | -- | <4.0 | +15%,-10% (min.+0.48, -0.32mm) | -- | 2-3 | +12%,-10% |

| 4-20 | +12.5%,-10% | >3 | +/-10% | |||

| >20 | +/-10% | |||||

| ASME SA-179M ASME SA-192M ASME SA-209M ASME SA-210M ASME SA-231M JIS G 3461 JIS G 3462 | -- | 2.41-3.8 | +35%, -0% | ≤38.1 | -- | +20%,-0% |

| 3.8-4.6 | +33%,-0% | >38.1 | -- | 22%,-0% | ||

| >4.6 | +28%,-0% | -- | -- | -- | ||

| ASME SA-106 ASME SA-335 | -- | All | +/12.5% | All | +/-10% | |

Note:

Positive material identification (PMI) testing is the examination of a material, usually a metallic alloy, to confirm the material is consistent with the user’s request.

Steel pipe delivery status(condition): cold / hard (BK), cold / soft (BKW), after cold stress relief annealing (BKS), annealing (GBK), normalized (NBK).

| Term | Symbol | Explanation |

|---|---|---|

| Cold-finished/hard (cold-finished as-drawn) | BK | No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

| Cold-finished/soft (lightly cold-worked) | BKW | After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

| Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

| Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

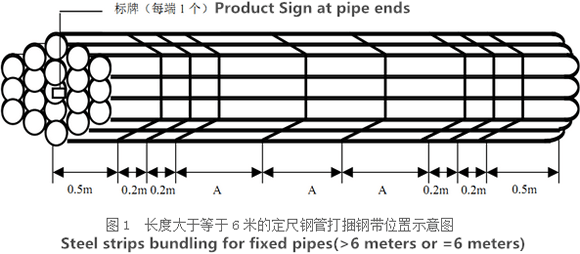

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

Our packing can meet any needs of the customers.