Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

GB 3087 Grade 20 tubes manufacture of high-quality carbon structural steel hot-rolled (extruded, expanded) and cold drawn (rolled) seamless steel tubes for various structural low-pressure and medium-pressure boilers and locomotive boilers.

GB 3087 Grade 20 tubes are a type of carbon structural steel seamless steel tubes that are designed for use in low and medium pressure boilers. They are manufactured in accordance with the requirements specified in the Chinese national standard GB 3087, which sets out the dimensions, shapes, masses, tolerances, technical requirements, testing methods, inspection rules, packaging, marking, and quality certificate of the tubes.

These tubes are made from high-quality carbon structural steel and have excellent mechanical properties, including high strength and good plasticity. They are widely used in various industrial applications that require high-quality carbon structural steel seamless tubes, such as in the construction of low and medium pressure boilers, heat exchangers, and other related equipment.

This standard specifies the dimensions, shape, weight, technical requirements, test methods, inspection rules, packaging, marking and quality specifications of seamless steel tubes for low and medium pressure boilers.

This standard is applicable to the manufacture of high-quality carbon structural steel hot-rolled (extruded, expanded) and cold drawn (rolled) seamless steel tubes for various structural low-pressure and medium-pressure boilers and locomotive boilers.

The provisions contained in the following standards constitute provisions of this standard by reference in this standard. At the time of publication, the editions indicated were valid. All standards will be revised and parties using this standard should explore the possibility of using the latest version of the following standards.

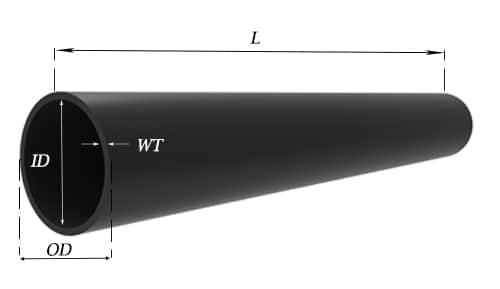

The outer diameter, wall thickness and theoretical weight of the steel pipe shall comply with the provisions of Table 1 of GB/T 17395-1998.

Steel pipes of different specifications as specified in Table 1 of GB/T 17395-1998 may be supplied through negotiation between the supplier and the buyer.

The allowable deviation of the outer diameter and wall thickness shall comply with the requirements of Table 1.

When the purchaser requests to supply according to advanced precision, it should be indicated in the contract.

After consultation between the supplier and the buyer, and in the contract, it can produce steel pipes with deviations from those specified in Table 1.

| Type of steel pipe | Outer diameter(mm) | Tolerance | ||

| ordinary | advanced | |||

| Hot rolled tube | OD | ≤159 | ±10%(min±0.50mm) | ±0.75%(min±0.40mm) |

| >159 | ±1.0% | ±0.90% | ||

| WT | ≤20 | +15.0%(min+0.45mm) | ±10%(min±0.30mm) | |

| -12.5% -0.35mm) | ||||

| >20 | ±12.5% | ±10% | ||

| OD≥351 | ±15% | |||

| Cold drawn tube | OD | ±0.40mm | ±0.20mm | |

| >30-50 | ±0.45mm | ±0.25mm | ||

| >50 | ±1.0% | ±0.75% | ||

| WT | 1.5-3.0 | +15% -10% | ±10% | |

| >3.0 | +12.5% -10% | ±10% | ||

| Steel Grade | C | Si | Mn | S | P | Cr |

|---|---|---|---|---|---|---|

| 10 | 0.07-0.13 | 0.17-0.37 | 0.35-0.65 | 0.02 | 0.025 | ≤0.15 |

| 20 | 0.17-0.23 | 0.17-0.37 | 0.35-0.65 | 0.02 | 0.025 | ≤0.25 |

length

The usual length of steel pipes is specified as follows:

Hot-rolled (extruded, expanded) steel pipe……………………………………………………4000~12000mm;

Cold drawn (rolled) steel pipe………………………………………………………… 4000~10500mm.

Length and length of the ruler

The length of the fixed length and the length of the double scale should be within the normal length range, and the full length tolerance is mm.

The length of each double ruler is set as follows:

OD ≤ 159mm…………………………………………………………5~10mm;

Outside diameter>159mm…………………………………………………………10~15mm.

Range length

The length of the range should be within the usual length range.

The bending of the steel pipe shall not be greater than the following:

Wall thickness ≤ 15mm…………………………………………………………1.5mm/m;

Wall thickness >15mm…………………………………………………………2.0mm/m;

Thermal expansion tube with an outer diameter of ≥ ……………….. 3.0mm/m.

The end faces of the steel pipe should be perpendicular to the axis of the steel pipe, and the burrs of the cut should be removed.

According to the requirements of the purchaser, the supplier and the buyer shall negotiate and indicate in the contract that the out-of-roundness and wall thickness of the same section of steel shall not exceed 80% of the outer diameter and wall thickness, respectively.

The delivery weight of steel pipes shall comply with the provisions of GB/T 19395. The density of the steel is calculated as 7.85 kg/dm3.

A steel pipe with an outer diameter of 76 mm and a wall thickness of 3.5 mm made of steel No. 10:

a) Hot-rolled steel pipe, the outer diameter and wall thickness are of ordinary grade accuracy, and the length is 3000mm.

10-76×3.5×3000 times—GB 3087—1999

b) Cold drawn (rolled) steel pipe, the outer diameter is advanced precision, the wall thickness is ordinary precision, and the length is 5000mm

Cold 10-76 high × 3.5 × 5000 times – GB 3087-1999

Table 2 Chemical composition of steel pipes

Standard issuing unit: National Quality and Technical Supervision Bureau approved 1999-11-01

Implementation date: 2000-08-01 implementation

The steel pipe is made of steel No. 10 and No. 20, and the chemical composition (melting analysis) shall comply with the provisions of GB/T 699. The steel pipe is inspected according to the olefinic components.

When the requester requests the analysis of the finished product, it should be indicated in the contract.

The chemical composition allowable deviation of the finished steel pipe shall comply with the provisions of GB/T222.

Method of manufacturing steel

Steel shall be manufactured by electric furnace, oxygen converter or open hearth method. When the manufacturer specifies a certain manufacturing method, it shall be indicated in the contract; the steel directly used for continuous casting billet must be refined outside the furnace.

Manufacturing method of tube blank

The tube blank can be produced by a hot rolling method, and a continuous casting billet or a steel ingot can also be used. Hot rolled tube blanks shall comply with the provisions of YB/T 5222.

Manufacturing method of steel pipe

The steel pipe can be manufactured by a hot rolling (extrusion, expansion) or cold drawing (rolling) seamless method. When the purchaser specifies a certain manufacturing method, it should be indicated in the contract.

Steel pipes shall be delivered in hot rolled or heat treated condition. The finishing temperature of the steel pipe delivered in the hot rolled state shall not be less than Ar3.

Delivery conditions The longitudinal mechanical properties of steel pipes are to comply with the requirements of Table 3.

| Steel pipe | Wall thickness (mm) | Tensile strength (MPa) | Yield Strength (MPa) | Elongation % |

|---|---|---|---|---|

| 10 | / | 335-475 | 195 | 24 |

| 20 | <15 | 410-550 | 245 | 20 |

| ≥15 | 225 |

The high-temperature transient performance of the steel pipe used for medium-pressure boiler superheated steam pipe shall comply with the provisions of Table 4. The purchaser shall indicate the purpose of the steel pipe in the contract.

According to the requirements of the purchaser, the supplier and the buyer shall negotiate and indicate the test temperature in the contract, and the supplier shall provide the actual high-temperature transient performance data of the steel pipe.

| Steel grade | Sample status | Temperature,℃ | |||||

|---|---|---|---|---|---|---|---|

| 200 | 250 | 300 | 350 | 400 | 450 | ||

| 10 | Delivery status | 165 | 145 | 122 | 111 | 109 | 107 |

| 20 | 188 | 170 | 149 | 137 | 134 | 132 | |

The steel pipe should be hydraulically tested one by one.

The supplier can replace the hydraulic test with eddy current testing. Ultrasonic testing or magnetic flux leakage testing can also be used instead of hydraulic testing after consultation between the supplier and the buyer. When using eddy current flaw detection, the grade A hole of GB/T 7735-1994 should be used; when ultrasonic flaw detection, the depth grade of the longitudinal notch groove on the outer surface of the comparison sample tube should meet the requirements of C8 in GB/T5777-1996; The longitudinal notch groove on the outer surface of the comparative sample tube shall comply with the provisions of N12.5 in GB/T 12606-1999, with a minimum depth of 0.5 mm and a maximum depth of 1.5 mm.

Steel pipes with an outer diameter of more than 22mm to 400mm and a wall thickness of not more than 10mm shall be subjected to a flattening test.

No cracks or cracks shall appear on the specimen after the flattening test.

According to the requirements of the purchaser, the supply and demand sides negotiate and indicate in the contract that the steel pipe made of No. 10 steel can be subjected to the crimping test.

The curling width (measured by the inner wall) shall not be less than 12% of the nominal inner diameter, nor less than 1.5 times the nominal wall thickness, and the curling angle shall be 90°. No cracks or cracks shall occur outside the sample curl after crimping.

According to the requirements of the purchaser, the supply and demand sides negotiate and indicate in the contract that the steel pipe with a wall thickness of not more than 8 mm can be subjected to a flare test with a top taper of 30°, 45° or 60°. No cracks or cracks shall appear on the specimen after flaring.

The flaring ratio of the outer diameter of the sample after flaring shall comply with the requirements of Table 5.

| Steel grade | steel pipe outer diameter expansion rate,% | ||

|---|---|---|---|

| Inside diameter / outer diameter | |||

| ≤0.6 | >0.6-0.8 | >0.8 | |

| 10 | 12 | 15 | 19 |

| 20 | 10 | 12 | 17 |

Steel pipes with an outer diameter of not more than 22 mm shall be subjected to a bending test with a bending angle of 90° and a radius of curvature of six times the outer diameter of the steel pipe. There must be no cracks or cracks in the bend.

According to the requirements of the purchaser, the supply and demand sides negotiate and indicate in the contract that the steel pipe for the locomotive boiler can be bent. The bending angle and the radius of the core are negotiated by both the supplier and the buyer.

For steel pipes directly manufactured by continuous casting billet or steel ingot, the supplier shall ensure that there are no white spots, inclusions, slag inclusions, skin turning, delamination and subcutaneous air bubbles on the cross-section acid-leaching low-strength test piece of the steel pipe or the blank.

The inner and outer surfaces of the steel pipe are not allowed to have cracks, folds, creases, crusting or separation, and these defects should be completely removed. The clearance depth shall not exceed the negative deviation of the nominal wall thickness, and the actual wall thickness at the cleaning site shall not be less than the minimum allowed by the wall.

Straight road allowed depth:

Cold drawn (rolled) steel pipe: not more than 4% of the wall thickness, the maximum depth is 0.3mm;

Hot-rolled (extruded, expanded) steel pipe: not more than 5% of the wall thickness, the maximum depth is 0.5mm.

Other defects where the depth does not exceed the wall thickness negative deviation and the remaining wall thickness is not less than the minimum allowed by the wall thickness are allowed to exist.

According to the requirements of the purchaser, after consultation between the supplier and the buyer, and in the contract, the steel pipe can be ultrasonically tested one by one. The depth of the longitudinal notch groove on the outer surface of the sample pipe should meet the requirements of C8 in GB/T 5777-1996.

The size of the steel pipe shall be measured one by one using gauges that meet the accuracy requirements.

The inner and outer surfaces of steel pipes shall be visually inspected one by one.

Other inspection items for steel pipes shall comply with the requirements of Table 6.

| Number | Test items | Experiment method | Number of samples |

|---|---|---|---|

| 1 | Chemical composition | GB/T 222 | Take one sample per furnace (tank) |

| GB/T 223 | |||

| 2 | Stretching test | GB/T 228 | Take one sample for each batch on each of the two steel pipes |

| 3 | Hydraulic test | GB/T 241 | Each |

| 4 | Flattening test | GB/T 246 | Take one sample for each batch on each of the two steel pipes |

| 5 | Crimping test | GB/T 245 | Take one sample for each batch on each of the two steel pipes |

| 6 | Flaring test | GB/T 242 | Take one sample for each batch on each of the two steel pipes |

| 7 | Bending test | GB/T 244 | Take one sample for each batch on each of the two steel pipes |

| 8 | Low magnification test | GB/T 226 | Take one sample for each batch on each of the two steel pipes |

| 9 | Ultrasonic flaw detection | GB/T 5777 | Each |

| 10 | Eddy current testing | GB/T 7735 | Each |

| 11 | Magnetic flux leakage test | GB/T 12606 | Each |

The inspection and acceptance of steel pipes shall comply with the provisions of GB/T 2102.

The steel pipes are inspected and accepted in batches. Each batch shall consist of steel pipes of the same grade, the same furnace (tank) number, the same specification and the same heat treatment system (heating).

All pipe sections taken from double-length long seamless steel pipes shall be considered as one.

The number of roots of each batch of steel pipes does not exceed the following:

The outer diameter is not more than 76mm, and the wall thickness is not more than 3mm………………………………………………400 PCS;

Outer diameter is greater than 351mm…………………………………………………………………………50 PCS;

Other sizes of steel pipes………………………………………………………………………………200 PCS.

When the number of remaining steel pipes is not less than 50% as specified above, it shall be listed as a batch; if it is less than 50% of the above, it may be incorporated into the same grade, the same furnace (can) number, the same specification and the same heat treatment system (furnace) Next) in the adjacent batch.

The sampling quantity of each inspection item of each batch of steel pipe shall be as specified in Table 6.

The re-inspection and determination rules of steel pipes shall comply with the provisions of GB/T 2102.

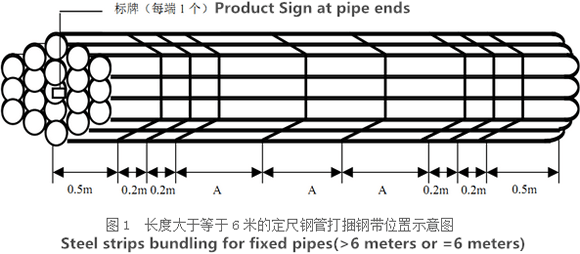

The packaging, marking and quality specifications of steel pipes shall comply with the provisions of GB/T 2102.

According to incomplete statistics, there are more than 240 national standard steel pipe production enterprises and more than 250 seamless steel pipe units.

Structural pipe (GB / T8162-1999) is used for the mechanical structure and general structure of seamless pipes.

Seamless pipe for liquid distribution (GB / T8163-1999) is a general seamless pipe for the transport of water, oil, gas and other liquids.

Seamless pipe is used for supply or transportation of water, oil, gas and other liquids under the specification of seamless pipe (GB / T8163-1999).

Correctly cooled or cold-rolled seamless steel pipe (GB3639-83) is used for mechanical structure, hydraulic equipment, high precision and surface finish. Selecting machines that produce seamless precision tubes or hydraulic equipment, etc., can greatly save mechanical processing time, improve material utilization, while helping to improve product quality.

Seamless pipe (GB3639-83) is basically improved the product quality though reduce the mechanical processing time and improve the material standard and quality. But it requires that it should be properly made by cooled or cold rolled seamless steel pipe (GB3639-83).

Low and medium pressure boiler pressure pipes (GB3087-1999) are used for the production of various low and medium pressure steam pipes, boiler water pipes and boilers with superheated steam, chimneys, small chimneys and domes use high quality hot rolled steel structures and cold drawn (laminated) seamless pipes.

Low and medium pressure boiler pressure pipe (GB3087-1999) is specialised for making of various low and medium pressure steam pipes, boiler water pipes and boilers with superheated steam, chimneys, and small chimneys.

High-pressure steam boiler pipe (GB5310-1995) is used for the production of high pressure and on the boiler surface pressure of hot water pipes made of high quality carbon steel, alloy steel and steel rust-free. (Working pressure is greater than 9.8Mpa, working temperature 540-650 degrees Celsius)

High quality carbon steel, alloy steel and steels are always required high pressure steam boiler pipe (GB5310-1995) for transportation and holding for liquid, steam, etc.

Pipeline for geological drilling (YB235-70) is a steel pipe for core drilling. It can be divided into drill pipe, neck drill, core tube, shell tube and sediment.

Core drilling is done though geological drilling (YB235-70) steel pipe and it’s segregated into drill pipe, neck drill, core tube, shell tube and sediment.

Piping (GB / T9711.1) is the supply of natural gas and other liquids such as oil and other seamless steel pipes (such as underground pipes and low temperature pipes).

High Pressure Cylinder Tube (GB18248) is used to produce oxygen cylinders, cylinder cylinders, natural gas cylinders, energy cylinders and other gas cylinders for seamless steel tubes.

Seamless steel pipe (GB / T9711.1) is used for the transporting and supplying of natural gas and other liquids such as oil.

Oxygen cylinders, cylinder cylinders, natural gas cylinders, energy cylinders and other gas cylinders is built by the High Pressure Cylinder Tube (GB18248) for seamless steel tubes.

Half-shaft automobile with seamless pipe (GB3088-82) is the manufacture of automobile tires and axles made of high-quality carbon structural steel and alloy steel pipes that melt the alloy structure.

Seamless pipe can be used in manufacturing of automobile tire and most of essential component of automobile industries. This specification consider under the standard of Half-shaft automobile with seamless pipe (GB3088-82).

Seamless steel pipe for ships (GB5213-85) is the production of grade I pressure piping, pressure pipe systems, boilers and seamless steel pipe coils. Carbon steel seamless pipe temperature does not exceed 450 ℃, seamless steel alloy steel pipe temperature of more than 450 ℃.

If the carbon steel pipe temperature does not exceed 450 ℃, it can be used for the production of grade I pressure piping and it consider under the standard of Seamless steel pipe for ships (GB5213-85)

Stainless steel structural stainless steel (GB / T14975-1994) is widely used in the fields of chemicals, petroleum, textiles, medical, food, machinery and other industries. Welded pipe and structural parts and parts made of hot stamping stainless steel, squeeze and seamless tubes.

Stainless steel structural steel (GB / T14975-1994) is used for the purpose of chemicals, petroleum, textiles, medical, food, machinery and other essential purpose works in different industries. Stainless tube considers all the function of squeeze and moulding with help of welded pipes and structural parts.

Stainless steel pipe for liquid distribution (GB / T14976-1994) is a seamless (extruded) and cold (laminated) seamless pipe made of stainless steel to transport liquids.

Liquid transportation is highly appreciated by the use of stainless steel pipe (GB / T14976-1994) but it is mandatory that seamless steel is cold laminated.

High pressure hose for chemical fertilizer equipment (GB6479-2000) suitable for working temperature -40 – 400 ℃, working pressure of chemical equipment 10 – 30Ma and carbon steel structural pipe High-grade seamless steel and alloy tubes.

Chemical fertilizer equipment (GB6479-2000) is used for the high pressure hose and it suits under the temperature of -40 – 400 ℃, working pressure of chemical equipment 10 – 30Ma and carbon steel structural pipe High-grade seamless steel and alloy tubes.

Uncured Pipes for Cracking Petroleum (GB9948-88) is a furnace tube, heat exchanger and seamless pipe for refineries.

Drill Diamond Core Drill (GB3423-82) is used for drilling diamond core drill, core rod, seamless pipe.

Seamless pipe drill diamond core drill (GB3423-82) is used for the drilling of diamond.

Oil Drill Tubing (YB528-65) is a seamless tube that thickens or thickens at both oil drills. The steel pipe is divided into two types of wire and wireless, and the wire is connected to the joint.

Diesel engine with high pressure pipe (GB3093-86) is the production of diesel injection system for high pressure pipe with no welded pipe.

Diesel engine with high pressure pipe (GB3093-86) is used for the production of diesel injection system for high pressure pipe, it doesn’t required welded pipe.

The internal precision pipe for hydraulic and pneumatic cylinders (GB8713-88) is a precision seamless pipe that is cold-rolled or cold-rolled with an accurate inner diameter for the production of hydraulic cylinders. and pneumatic. Columns, columns, can also be used for other cylinders and columns.

The production of hydraulic cylinders and pneumatic Columns, Columns these products require proper precision seamless pipe and the pipe should be cold- rolled or cold –rolled with an accurate inner diameter.

| Deviation level | Standardized outer diameter tolerance |

|---|---|

| D1 | ±1.5%,min ±0.75 mm |

| D2 | ±1.0%。min ±0.50 mm |

| D3 | ±0.75%.min±0.30 mm |

| D4 | ±0.50%。min ±0.10 mm |

| Process | Size(mm) | Tolerance | |

|---|---|---|---|

| Hot-rolled | O.D. | <351 | +/-1.0% D(+/-0.50min) |

| >=351 | +/-1.25% D | ||

| W.T. | <=25 | +/-12.5% S(+/-0.40 min) | |

| Cold drawn | O.D. | <=30 | +/-0.20 |

| 30-50 | +/-0.30 | ||

| >50 | +/-0.75% D | ||

| W.T. | <=3 | +12.5% S, -10% S | |

| >3 | +/-10% S | ||

The production of our seamless pipes is tightly regulated and all of the pipes we stock have been fully tested to international standards to ensure we only supply the highest quality products.

| Product name | Executive standard | Dimension (mm) | Steel code/ Steel grade |

|---|---|---|---|

| Black and Hot-dipped Zinc-coated Steel Pipes Seamless | ASTM A53 | 0.3-1200 x 1.0-150 | GR.A, GR.B, GR.C |

| Seamless Carbon Steel for High Temperature Service | ASTM A106 | 10.3-1200 x 1.0-150 | GR.B, GR.C |

| Seamless Cold-drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes | ASTM A179 | 10.3-426 x 1.0-36 | Low Carbon Steel |

| Seamless Carbon Steel Boiler Tubes for High Pressure | ASTM A192 | 10.3-426 x 1.0-36 | Low Carbon Steel |

| Seamless Cold-drawn Intermediate Alloy Steel Heat-exchanger and Condenser Tubes | ASTM A199 | 10.3-426 x 1.0-36 | T5, T22 |

| Seamless Medium-carbon Steel Boiler and Superheater Tubes | ASTM A210 | 10.3-426 x 1.0-36 | A1, C |

| Seamless Ferritic and Austenitic Alloy Steel Boiler, Superheater and Heat-exchanger Tubes | ASTM A213 | 10.3-426 x 1.0-36 | T5, T5b, T9 , T11, T22 ,T91 |

| Seamless Carbon and Alloy Steel for Mechanical Tubing | ASTM A333 | 1/4"-42" x SCH20-XXS | Grade1 Gr. 3,Gr..6, Gr.8 , Gr. 9 |

| Seamless Cold-drawn Carbon Steel Feedwater Heater Tubes | ASTM A556 | 10.3-426 x 1.0-36 | A2, B2 |

| Round and shaped steel cold formed welded and seamless carbon steel structural pipe. | ASTM A500 | OD :10.3-820 x 0.8- 75 | Grade A, B, C, D |

| Carbon and alloy steel mechanical tubing, either hot-finished or cold-finished | ASTM A519 | 10.3-426 x 1.0-36 | 1020, 1025, 4130, 4140 |

| For seamless ferritic alloy-steel pipe for high-temperature service | ASTM A335 | 1/4"-42" x SCH20-XXS | A/SA 335 P1, P2, P11, P12, P15, P22, P91, P92, P122 |

Cold Drawn Seamless Mechanical Tubing (CDS) is a cold drawn 1018/1026 steel tube which offers uniform tolerances, enhanced machinability and increased strength and tolerances compared to hot-rolled products.  Cold drawn steel tube is with hot-rolled steel coil as raw material, and tandem cold rolling pickled to remove oxide scale, its finished rolling hard roll, rolling hard volumes due to the continuous cold deformation caused by cold hardening strength, hardness increased indicators declined tough plastic, stamping performance will deteriorate, which can only be used for simple deformation of the parts. Rolling hard roll can be used as the raw material of the hot-dip galvanizing plant, hot dip galvanizing line set annealing line. Rolling hard roll weight is generally 6 to 13.5 tons, the coil diameter of 610mm.

Cold drawn steel tube is with hot-rolled steel coil as raw material, and tandem cold rolling pickled to remove oxide scale, its finished rolling hard roll, rolling hard volumes due to the continuous cold deformation caused by cold hardening strength, hardness increased indicators declined tough plastic, stamping performance will deteriorate, which can only be used for simple deformation of the parts. Rolling hard roll can be used as the raw material of the hot-dip galvanizing plant, hot dip galvanizing line set annealing line. Rolling hard roll weight is generally 6 to 13.5 tons, the coil diameter of 610mm.

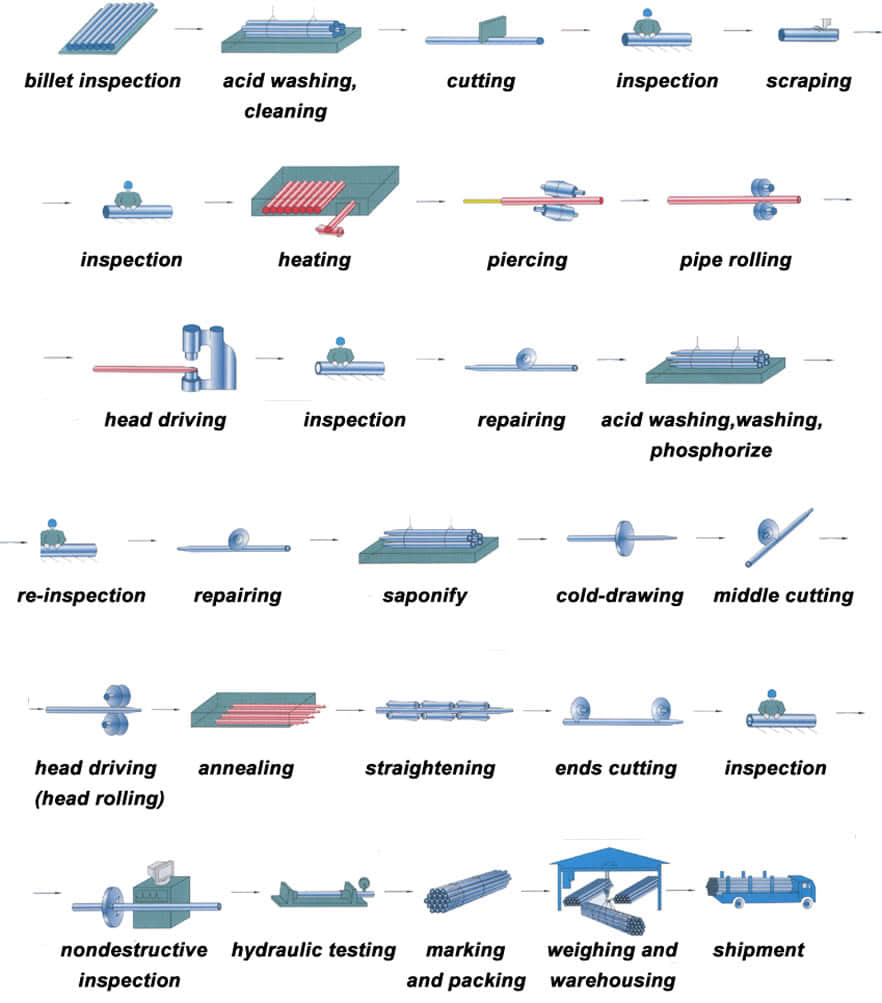

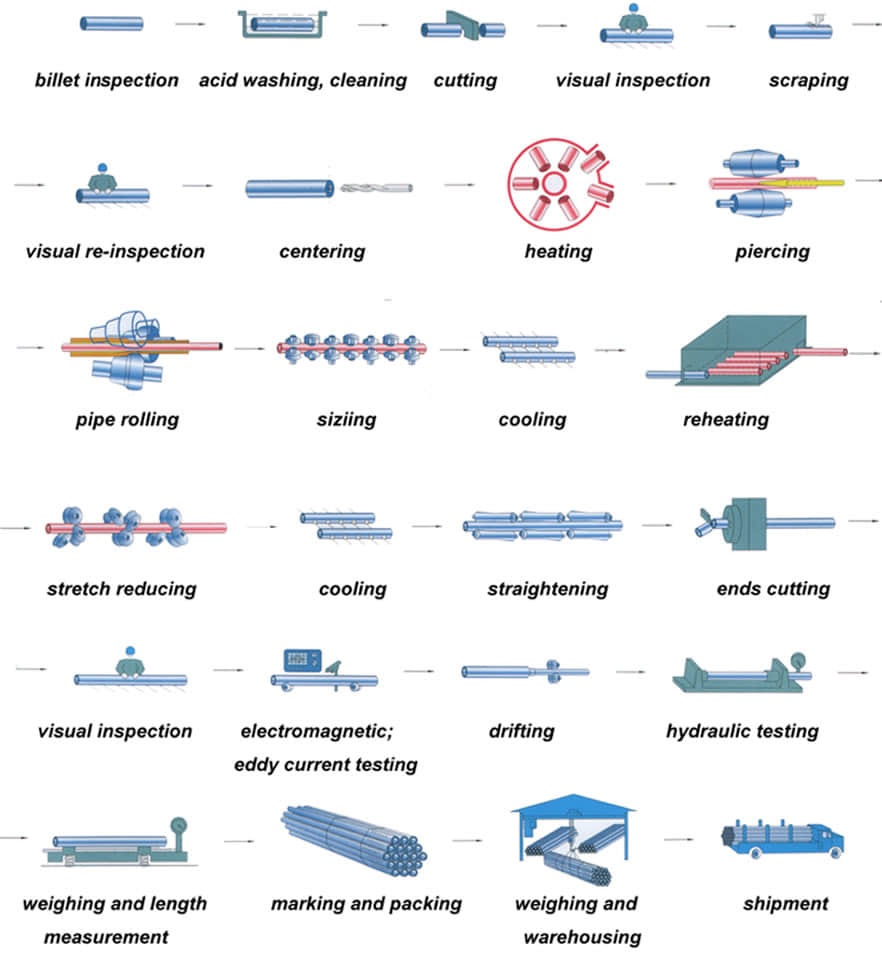

Hot-rolled seamless steel pipe production base deformation process can be summarized as three stages: perforation, extension and finishing.  The main purpose of the perforation process is to become a solid round billet piercing hollow shell. Capillary in the specifications, accuracy and surface quality can not meet the requirements of the finished product, further improvements are needed to deform the metal through. The main purpose of the stretching machine is further reduced sectional view (main compression wall) for a larger axial extension, so that the capillary improved dimensional accuracy, surface quality and organizational performance. After stretching machine rolled steel pipe shortage collectively need further molding mill in order to achieve the requirements of the finished pipe. Rolled steel due to pass in the method widely used in the production of seamless steel tubes. So far, due to the method pass rolling steel can be divided into two categories: core pension without rolling rolling (hollow body rolling), and with the mandrel. Sizing machines, reducing mill and stretch reducing mill belonging to the hole without mandrel type continuous rolling mills are generally coffin. Its main purpose is to reduce the diameter of the deformation process or sizing get finished steel, the wall thickness of process control, can make thinning, thickening or nearly unchanged. All the traditional hole-type rolling machine with mandrel belong to extend machine. The main purpose is to reduce the deformation process perforated capillary wall thickness and outer diameter roll passes in the deformation zone and the mandrel posed, for a larger axial extension. At the same time a certain improvement in the organization, performance, accuracy, surface quality.

The main purpose of the perforation process is to become a solid round billet piercing hollow shell. Capillary in the specifications, accuracy and surface quality can not meet the requirements of the finished product, further improvements are needed to deform the metal through. The main purpose of the stretching machine is further reduced sectional view (main compression wall) for a larger axial extension, so that the capillary improved dimensional accuracy, surface quality and organizational performance. After stretching machine rolled steel pipe shortage collectively need further molding mill in order to achieve the requirements of the finished pipe. Rolled steel due to pass in the method widely used in the production of seamless steel tubes. So far, due to the method pass rolling steel can be divided into two categories: core pension without rolling rolling (hollow body rolling), and with the mandrel. Sizing machines, reducing mill and stretch reducing mill belonging to the hole without mandrel type continuous rolling mills are generally coffin. Its main purpose is to reduce the diameter of the deformation process or sizing get finished steel, the wall thickness of process control, can make thinning, thickening or nearly unchanged. All the traditional hole-type rolling machine with mandrel belong to extend machine. The main purpose is to reduce the deformation process perforated capillary wall thickness and outer diameter roll passes in the deformation zone and the mandrel posed, for a larger axial extension. At the same time a certain improvement in the organization, performance, accuracy, surface quality.

Before cutting pipe and tubing No matter the material, measure the diameter of the pipe or tube to be cut to ensure that you use the right-size tube cutter for the job. When determining how to make a straight cut, use a tape measure and a pencil or other writing instrument to mark on the surface where you want to cut. If possible, mark around the circumference of a pipe, especially when cutting with a handsaw. Ensure that a cut is as straight as possible by securing the pipe with a vise, clamp, miter box or even duct tape to keep the length from shifting out of place while cutting. After cutting pipe and tubing

Geometrical inspection of steel pipes The outer diameter, wall thickness, bending and length of the steel pipe can be inspected on the inspection table with an outer caliper, a micrometer and a bending ruler, and a length tape measure.

Take seamless steel pipe as an example, there are some tolerances that affect quality. Noting this, and you will get a better pipe.

Weight tolerance

For pipe NPS 12 (DN300, 323.8mm) and under, the weight shall vary within -3.5% / +10%.

For pipe over NPS 12 (DN300, 323.8mm), the weight shall vary within -5% / +10%.

Pipe of NPS 4 (DN100, 114.3mm) and smaller may be weighed in convenient lots; pipe in sizes larger than NPS 4 shall be weighed separately.

Quantity tolerance

Normally mills take -10% to +10% tolerance, but TPMCSTEEL keeps ±3% variation.

Length tolerance

For Seamless pipe& tube, if definite cut lengths are ordered, the length shall vary within -0mm / +6mm.

| Pipe types | Pipe Szie(mm) | Tolerances | |

|---|---|---|---|

| Hot rolled | OD | <50 | ±0.50mm |

| ≥50 | ±1% | ||

| WT | <4 | ±12.5% | |

| ≥4-20 | +15%, -12.5% | ||

| >20 | ±12.5% | ||

| Cold drawn | OD | 6-10 | ±0.20mm |

| 10-30 | ±0.40mm | ||

| 30-50 | ±0.45 | ||

| >50 | ±1% | ||

| WT | <1 | ±0.15mm | |

| >1-3 | + 15%, – 10% | ||

| >3 | + 12.5%, – 10% | ||

| Standard | Hot finished seamless tube | Cold flnished seamless tube | ||

|---|---|---|---|---|

| Out diameter (mm) | Tolerance | Out diameter (mm) | Tolerance | |

| EN10216-1 | ≤100 | +/-0.75% (min.+/-0.5mm) | All | +/-0.5% |

| EN10216-2 | (min. +/-0.30mm) | |||

| DIN17175 | >100 | +/-0.90% | ||

| GB/T 3087 | ≤460 | +/-0.75% (min.+/-0.5mm) | 10-30 | +/-0.40mm |

| >30-50 | +/-0.45mm | |||

| >50 | +/-1.0% | |||

| GB/T 5310 GB/T 9948 GB/T 6479 | <57 | +/-0.40mm | ≤30 | +/-0.20mm |

| 57-325 | +/-0.75% | >30-50 | +/-0.30mm | |

| >325-460 | +1%,-2mm | >50 | +/-0.8% | |

| ASME SA-179M ASME SA-192M ASME SA-209M ASME SA-210M ASME SA-213M JIS G 3461 JIS G 3461 | ≤101.6 | +0.4, -0.8mm | <25.4 | +/-0.10mm |

| >25.4-38.1 | +/-0.15mm | |||

| >38.1-50.8 | +/-0.20mm | |||

| 101.6-190.5 | +0.4, -1.2mm | >50.8-63.5 | +/-0.25mm | |

| >63.5-76.2 | +/-0.30mm | |||

| >76.2 | +/-0.38mm | |||

| ASME SA106 ASME SA335 | ≤48.3 | +/-0.40mm | ≤48.3 | +/-0.40mm |

| 48.3-114.3 | +/-0.79mm | |||

| 114.4-219.1 | +1.59, -0.79mm | |||

| 219.2-323.9 | +2.38, -0.79mm | >48.3 | +/-0.79mm | |

| >324 | +/-1.0% | |||

| Standard | Hot finished seamless tube | Cold flnished seamless tube | ||||

|---|---|---|---|---|---|---|

| DIN17175 | Out diameter OD(mm) | Wall thickness T(mm) | Tolerance | Out diameter (mm) | Wall Thickness T(mm) | Tolerance |

| ≤130 | S≤2Sn | +15%, -10% | -- | All | +/-10% (min. +/-0.2mm) |

|

2Sn| +12.5%, -10% |

| |||||

| S>4Sn | +-/9% | |||||

| >130 | S≤0.05da | +17.5%, -12.5% | ||||

0.05da| +/-12.5% |

| |||||

| S>0.11da | +/-10% | |||||

| EN 10216-1 EN 10216-2 | ≤219.1 | - | +/-12.5% (min.+/-0.4mm) |

|||

| -- | T/D≤0.025 | +/-20% | ||||

0.025| +/-15% |

| |||||

0.05| +/-12.5% |

| |||||

0.1| +/-10% |

| |||||

| GB/T 3087 | -- | ≤20 | +15%,-12.5% (min.+0.45, -0.35mm) | -- | 1.0-3.0 | +15%, -10% |

| >20 | +/-12.5% | -- | >3 | +12.5%, -10% | ||

| GB/T 5310 GB/T 9948 GB/T 6479 | -- | <4.0 | +15%,-10% (min.+0.48, -0.32mm) | -- | 2-3 | +12%,-10% |

| 4-20 | +12.5%,-10% | >3 | +/-10% | |||

| >20 | +/-10% | |||||

| ASME SA-179M ASME SA-192M ASME SA-209M ASME SA-210M ASME SA-231M JIS G 3461 JIS G 3462 | -- | 2.41-3.8 | +35%, -0% | ≤38.1 | -- | +20%,-0% |

| 3.8-4.6 | +33%,-0% | >38.1 | -- | 22%,-0% | ||

| >4.6 | +28%,-0% | -- | -- | -- | ||

| ASME SA-106 ASME SA-335 | -- | All | +/12.5% | All | +/-10% | |

Note:

Positive material identification (PMI) testing is the examination of a material, usually a metallic alloy, to confirm the material is consistent with the user’s request.

Steel pipe delivery status(condition): cold / hard (BK), cold / soft (BKW), after cold stress relief annealing (BKS), annealing (GBK), normalized (NBK).

| Term | Symbol | Explanation |

|---|---|---|

| Cold-finished/hard (cold-finished as-drawn) | BK | No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

| Cold-finished/soft (lightly cold-worked) | BKW | After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

| Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

| Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

Our packing can meet any needs of the customers.

Need to inquire about our products? Fill out the form below and our staff will be in touch!

Q: How long is your delivery time? A: The delivery time of customized products is generally 25 35 days, and non customized products are generally shipped within 24 hours after payment. Q: Do you provide samples? Is it free? A: If the value of the sample is low, we will provide it for free, but the freight needs to be paid by the customer. But for some high value samples, we need to charge a fee. Q: What are your payment terms? A: T/T 30% as the deposit,The balance payment is paid in full before shipment Q: What is the packaging and transportation form? A: Non steaming wooden box and iron frame packaging. Special packaging is available according to customer needs. The transportation is mainly by sea. Q: What is your minimum order quantity? A: There is no minimum order quantity requirement. Customized products are tailor made according to the drawings provided by the customer.