Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

These ASTM specified SA178a Boiler Tubes are produced with a minimum wall thickness made from carbon steel alloys as well as carbon- manganese steel.

ASTM A178 is a specification which covers standards for electric resistance welded tubes, which are abbreviated as ERW SA178 Boiler Tube. These ASTM specified SA178a Boiler Tubes are produced with a minimum wall thickness made from carbon steel alloys as well as carbon- manganese steel. This ASTM SA178 Grade A Electric-Resistance Welded Carbon Steel Boiler Tubes are designed to be used in boiler flues, boiler tubes, superheater flues, and safe ends as well. While the specification covers various alloy groups in terms of grades, the SA 178 Gr A Tubes are manufactured from low carbon steel. This low carbon based SA178a Tube Material, although soft is known to have outstanding ductility and toughness properties along with being machinable and weldable. Also, our clients prefer using this Carbon Steel ASTM A178 Tubing because it is a vert cost-effective piping solution.

ASTM A178 standard referes to electric-resistance-welded tubes with minimum-wall-thickness. Materials are carbon steel and carbon-manganese steel, ASTM A178 pipe and tube is to be used in boiler tubes, boiler flues, superheater flues and safe ends. Steel Grades A (low-carbon steel), C (medium-carbon steel), or D (carbon-manganese steel). Manufacturing processes must include heat treatment, welding after cooling. Crush test shall be performed if required by customer.

| Grade | C | Mn | P | S | Si |

|---|---|---|---|---|---|

| Grade A Low carbon steel | 0.06-0.18 | 0.27-0.63 | 0.035 | 0.035 | ... |

| Grade C Medium Carbon Steel | 0.35 Max | 0.80 Max | 0.035 | 0.035 | ... |

| Grade D Manganess Steel | 0.27 Max | 1.00-1.50 | 0.03 | 0.015 | 0.10 Min. |

Chemical Composition

The steel shall conform to the requirements as to chemical composition prescribed in Table 1.

When a grade is ordered under this specification, sup- plying an alloy grade that specifically requires the addition of any element other than those listed in Table 1 is not permitted.

Product Analysis

1. When requested on the purchase order, a product analy- sis shall be made by the manufacturer or supplier from one tube per 100 pieces for sizes over 3 in. [76.2 mm] and one tube per 250 pieces for sizes 3 in. [76.2 mm] and under; or when tubes are identified by heat, one tube per heat shall be analyzed. The chemical composition thus determined shall conform to the requirements specified.

2. If the original test for product analysis fails, retests of two additional lengths of flat-rolled stock or tubes shall be made. Both retests, for the elements in question, shall meet the requirements of the specification; otherwise all remaining material in the heat or lot (Note 2) shall be rejected or, at the option of the producer, each length of flat-rolled stock or tube may be individually tested for acceptance. Lengths of flat- rolled stock or tubes which do not meet the requirements of the specifications shall be rejected.

| Grade | T.S. ksi [MPa] | Y.S. ksi [MPa] | EL. in 2" min. % |

|---|---|---|---|

| Grade C | 60 [415] | 37 [255] | 30 |

| Grade D | 70 [485] | 40 [275] | 30 |

Manufacture & Heat Treatment

The ASTM A178 Grade D steel shall be killed. ASTM A178 tubes shall be made by electric-resistance welding process. After welding, all tubes shall be heat treated at a temperature of 1650°F [900°C] or higher and followed by cooling in air or in the cooling chamber of a controlled-atmosphere furnace. Cold-drawn tubes shall be heat treated after the final cold-draw pass at a temperature of 1200°F [650°F] or higher.

Testing & Inspection

ERW tubes made from ASTM A178 steel may be tested or inspected in the following ways covering crush test, flattening test, flange test, tension test, reverse tension test, hydrostatic test, nondestructive electric test, dimension inspection, visual examination, as well as ultrasonic inspection.

NOTE 2—A lot consists of 250 tubes for sizes 3 in. [76.2 mm] and under and of 100 tubes for sizes over 3 in. [76.2 mm], prior to cutting to length.

Condenser steel tube,heat-exchanger tube,low carbon steel pipe,Resistance welded steel tube ,Bolier flues,Spoerheater flues and safe ends,ERW carbon steel pipes.

Manufacturing Process: ERW

Heat treatment: After welding,all tubes shall be heat treated at a temperature of 1650°F(900℃) or higher and followed by cooling in air or in the cooling chamber of a controlled-atmosphere furnace,Cold-drawn tubes shall be heat treated after the final cold-draw pass at a temperature of 1200°F(650℃)or higher.

Surface Condition: Finished tubes shall be free of scale,A slight amount of oxidation will not be considered as scale.

Mechanical Tests Required: Flattenting Test/Flaring test/Flange test/Crush test/Tension test/Reverse Flattening test/Hydrostatic or Nondestructive Electric Test

Usage Used in boiler, superheater, heat-exchanger and pressure equipment in Petrochemical factory, Refinery factory, sugar mill, power plant, power plant, shipbuilding.

Due to their comparable weldability & mechanical properties, these substances can be classed together. A base alloy mentioned in a separate ASME material standard with the identical UNS number shall be regarded as that P-Number when a base alloy with a UNS number Classification is given a P-Number. An engineering evaluation is required before changing the materials.

As compared to ASTM A178 C tubing, ASTM A178 Grade A tubing has a lower tensile strength. Both grades’ yield strengths and hardness varied as well. SA 178 Gr A boiler tubes have a lower yield strength and harder surface than SA 178 Gr C boiler tubes. Their applications have also changed as a result of all these modifications. Grade A pipes have the UNS number K01200, whereas grade C pipes have the UNS number K03503.

SA178A boiler tubing wall thicknesses & sizes typically fall within the range of 1/2 to 5 inches. [12.7 to 127 mm] in length & [0.035 to 0.360 inches] in width. The minimum wall thickness is [0.9 to 9.1 millimeters], included.

These ASTM standard SA178 grade A seamless tubes are built from carbon metal alloys, including carbon-manganese steel with a minimal wall thickness. Because of its characteristics, this pipe can be used in many different applications. Whenever rust or degradation mechanisms are engaged, SA178 Grade A Pipe offers a safety margin from unexpected loads and a longer survival duration.

There could be a significant change in the structural and nano-size deposition attributes (quantity, kind, and dimensions) after thermal treatment for SA178a Tube. This change may have a significant impact on the alloy’s ability to withstand corrosion. By strengthening the material, heat treatment can increase wear resistance.

The most essential technical purposes as well as particular automotive industries, specifically call for the usage of ASTM A178 A tubes. In particular, among many other goods with additional value, there is metal for Gas cylinders, API rating, a corrosion-resistant alloy of steel, important structural purpose metal, boiler excellence, auto-grading, precise pipes, & lower carbon grades.

Such tubes are used in various industries, including petroleum refining, chemical plants, power stations (thermal and nuclear), steelworks, sugarcane refineries, compressed gases, boilers apparatus, and general engineering. Such pipes are favored by the majority of people due to their resistance to corrosion.

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

|---|---|---|---|

| Electric-Resistance-Welded Steel Pipes | ASTM A135 | 42.2-114.3 x 2.11-2.63 | A |

| Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes | ASTM A178 | 42.2-114.3 x 2.11-2.63 | A, C,D |

| ERW and Hot-dip Galvanized Steel Pipes | ASTM A53 | 21.3-273 x 2.11-12.7 | A, B |

| Pipes for Piling Usage | ASTM A252 | 219.1-508 x 3.6-12.7 | Gr2, Gr3 |

| Tubes for General Structural Purpose | ASTM A500 | 21.3-273 x 2.11-12.7 | Carbon Steel |

| Square Pipes for General Structural Purpose | ASTM A500 | 25 x 25-160 x 160 x 1.2-8.0 | Carbon Steel |

| Mechanical tubing | ASTM A513 | 21.3-273 x 2.11-12.7 | carbon and alloy steel |

| Screwed and Socketed Steel Tubes | BS 1387 | 21.4-113.9 x 2-3.6 | Carbon Steel |

| Scaffolding Pipes | EN 39 | 48.3 x 3.2-4 | Carbon Steel |

| Carbon Steel Tubes for General Structure Purpose | JIS G3444 | 21.7-216.3 x 2.0-6.0 | Carbon Steel |

| Carbon Steel Tubes for Machine Structure Purpose | JIS G3445 | 15-76 x 0.7-3.0 | STKM11A, STKM13A |

| Carbon Steel Pipes for Ordinary Piping | JIS G3452 | 21.9-216.3 x 2.8-5.8 | Carbon Steel |

| Carbon Steel Pipes for Pressure Service | JIS G3454 | 21.7-216.3 x 2.8-7.1 | Carbon Steel |

| Carbon Steel Rigid Steel Conduits | JIS G8305 | 21-113.4 x 1.2-3.5 | G16-G104, C19-C75, E19-E75 |

| Carbon Steel Rectangular Pipes for General Structure | JIS G3466 | 16 x 16-150 x 150 x 0.7-6 | Carbon Steel |

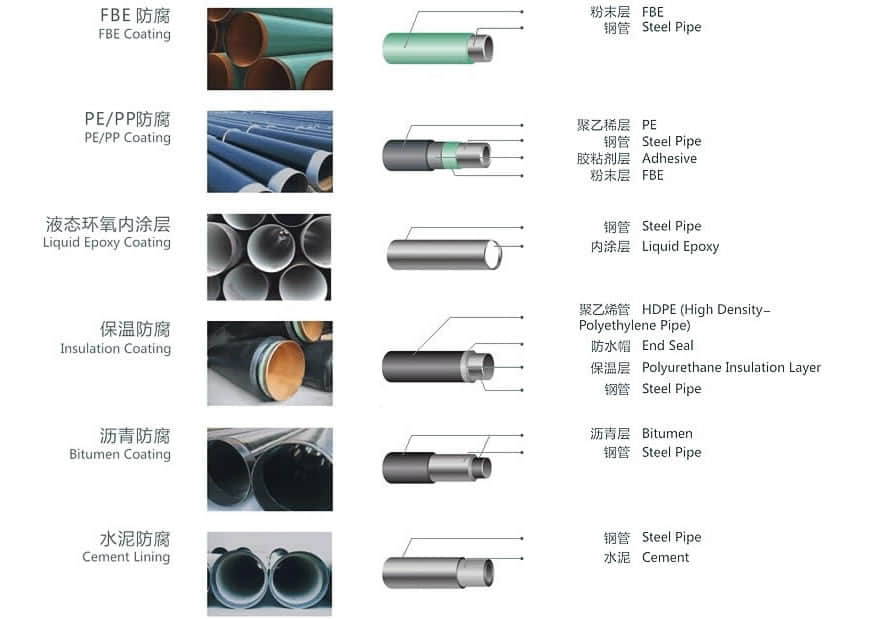

Pipeline coating is the most consistent and successful solution for protecting ERW pipes from corrosion, from moisture, other harmful chemicals. Anti-corrosion steel pipe is processed through the preservation process, which can effectively prevent or slow down the process in the transport and use of chemical or electrochemical corrosion reaction of steel pipe. Therefore pipe anti-corrosion layer is an important barrier to prevent soil erosion. A well-known foreign scholar put forward” 3PE france protective layer”, so far, anti-corrosion methods is widely used. Coated pipes offer high resistance to corrosion on pipes and provide many benefits such as: 1. Increased Flow Capacity – A coating on pipes helps provide a smoother surface thus improving gas and liquid flow within pipes. 2. Reduced Cost – The pipeline coating increases the pipes durability so they can be deployed with minimum maintenance cost even in the harshest environments. 3. Lower energy usage – Various studies have shown that pipelines that are internally coated use less energy for pumping and compression of products through pipes. This helps in increased saving over time. 4. Clean delivery of products – The inhibitors used for the protection products can also be minimized by the use of coated pipes for delivery of products. Thus, coating of pipelines can help you in reducing your maintenance cost and at the same time providing a corrosion free reliable protection.

The basic principles of urban gas pipeline coating selection:

2.1.External Coating 2.1.1 External Epoxy Coating

2.1.2 Polyethylene Coating

2.1.3 Polypropylene Coating

2.1.4 Polyurethane Coating

2.1.5 Polyolefin Coating

2.1.6 Tape Coating

2.1.7 Bitumen Coating

2.1.8 Coal-Tar Enamel Coating

2.1.9 Concrete Weighted Coating

5:External concrete coating.

2.1.10 Marine Coating

2.1.11 Other specification

2.2. Lining 2.2.1 Epoxy Lining

2.2.2 Bitumen Lining

2.2.3 Cement Mortar Lining

2.2.4 Shop Cement Lined Piping

Pipe Coating Products

Three Layer Polyethylene (3LPE) To improve anticorrosion performance and adhesion, an additional layer of epoxy primer is sprayed onto pipe surfaces prior to the adhesive layer and Polyethylene top layer application. Three Layer Polyethylene is suitable for service temperatures from 60°C to 80°C (85°C peaks). Typical coating thickness is from 1-2 mm to 3-5 mm. Three Layer Polypropylene (3LPP) If a wider service temperature range and high stiffness is required, adhesive and top layers, applied over primer layer, are based on polypropylene instead of polyethylene. Three Layer Polypropylene is suitable for service temperatures up to 135 °C (140°C peaks). Typical coating thickness is from 1-2 mm to 3-5 mm. Three Layer Polypropylene and Polyethylene Three Layer applications involve a thermoplastic coating applied to steel pipelines as a form of anticorrosion protection. This mechanical resistance is appropriate when the risk of particularly severe coating damages exist. The Three Layer process involved several steps. First, the pipe surface is blast cleaned to remove any external residue from the mill or storage. It is then heated and sprayed with a Fusion Bond Epoxy (FBE) primer followed by the application of an adhesive copolymer and polyolefin polymers that are wrap extruded, one over the other. Field applied products

Need to inquire about our products? Fill out the form below and our staff will be in touch!

Q: How long is your delivery time? A: The delivery time of customized products is generally 25 35 days, and non customized products are generally shipped within 24 hours after payment. Q: Do you provide samples? Is it free? A: If the value of the sample is low, we will provide it for free, but the freight needs to be paid by the customer. But for some high value samples, we need to charge a fee. Q: What are your payment terms? A: T/T 30% as the deposit,The balance payment is paid in full before shipment Q: What is the packaging and transportation form? A: Non steaming wooden box and iron frame packaging. Special packaging is available according to customer needs. The transportation is mainly by sea. Q: What is your minimum order quantity? A: There is no minimum order quantity requirement. Customized products are tailor made according to the drawings provided by the customer.