Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

The line pipes can be used for a wide range of petrol and gas transportation under sour service environment.

The line pipes can be used for a wide range of petrol and gas transportation under sour service environment.

Sunny Steel offer an extensive range of Line pipes used in sour service environment.

Sour service line pipes are produced accord to GB/T9711.3 and API 5L/ISO31813-2007.

Standard:

Application:

Sizes

Marking:

Delivery:

Line pipe steels used in sour service are prone to hydrogen-induced cracking (HIC) depending on metallurgical and environmental factors.

The metallurgical factors consist of alloying elements, microstructure, strength, segregation, and shape of non-metallic inclusions. Some environmental factors which influence HIC, also known as stepwise cracking (SWC), are the partial pressures of hydrogen sulfide (H2S) and carbon dioxide, temperature, pH of the medium, and aggressive ions, such as chloride. Many failures of sour gas line pipes have occurred around the world as a result of HIC.

Considerable effort has been expended by steel line pipe producers, users, and research organizations to understand the HIC mechanism, to develop a laboratory test method to identify and quantify material susceptibility to HIC, and to produce steels with greater HIC resistance. NACE International has developed a standard test, TM-02-84, for line pipe steels.

The method describes procedures for evaluating the resistance of pipeline steels to SWC induced by H absorption from aqueous sulfide corrosion. The test is applicable to line pipe with wall thicknesses of 5 mm to 30 mm. The procedure consists of exposing unstressed coupons to synthetic seawater saturated with H2S at ambient temperature and pressure at a pH in the range 4.8 to 5.4 for 96 h. The samples are sectioned, polished metallographically, and etched, if necessary, so that cracks can be distinguished from small inclusions, laminations, scratches, or discontinuities. Crack sensitivity ratio (CSR), crack length ratio (CLR), and crack thickness ratio (CTR) are calculated for each section. The average is determined for each coupon. In recent work by Canada’s Centre for Mineral and Energy

Technology in collaboration with the Canadian Standards Association (CSA) Sour Service Task Force, two parameters were determined experimentally for each of 19 line pipe steels:

(1) threshold H concentration (CthH) or the concentration of diffusible H in the steel above which cracking occurs and

(2) threshold pH (pHth) or the pH below which cracking occurs.

Sour services steel pipe is applied for pipelines in the corrosive environment.

As we know, line pipe corrosion is an important factor affecting its safety service and service life. It will cause the leakage of oil and gas pipeline, some cases even explosion.

Pipe corrosion has a big threaten to personal safety and environment pollution, so the production of sour service pipe is important. At present, the manufacture inspection standard for acid pipe mainly according to API Spec 5L.

1. Sour Service Pipe Definition

Sour service pipe mainly used in H2S environment. While H2S is a harmful chemicals that mostly easy to generate the corrosion.

According International regulation: When partial pressure of H2S reaches 300 pa, the line pipes used shall have the anti-acid corrosion performance.Sour service pipe includes NACE pipe.

2. How Sour Service Pipe Made

In API Spec 5L, the pipeline steel used for sour service pipe is purity fully-killed steel. (For normal line pipe steel material is grain-killed steel)

It shall be noted that, the high purity of steel can guarantee low S, P and other impurities.

In addition, the standard for the control and inspection of the inclusion shape of pipeline steel for sour service pipe is required. Because the hydrogen induced cracking caused by the inclusion is first determined in its form.

Moreover, As the pipeline steel production generally adopts controlled rolling process. Inclusion occur deformation during the rolling process. It is called linear or long strips in the rolling direction, leading to anisotropy of line pipe steel. Consequently, In order to improve the corrosion resistance of steel line pipe, the slag form should be controlled.

3. Chemical properties of sour service pipe

The content of C, P, S and carbon equivalent in the chemical composition of sour service pipe is relatively low than the normal line pipes, with a strictly control requirements. Especially for the content S, it is extremely harmful element in the corrosion environments, so for sour service pipe should control S maximum 0.002.

1). C and carbon equivalent effect to sour pipe

C and carbon equivalent: With the mass fraction of carbon increases, the HIC sensitivity increases. The reduction of carbon and carbon equivalent can improve the H2S corrosion resistance of pipeline steel. And it will generate the harmful martensite formulas, which is very sensitive to H bubbles for the hot rolled steel.

2). P element for sour pipe

The P element is an easy to segregation element, so the increase of phosphorus mass fraction will lead to the increase of banded structure, thus increasing the sensitivity of the steel HIC.

3). S element effect for sour pipe

S element can promote the occurrence of HIC, the higher the sulfur content of the pipe body material, the easier to produce HIC. In addition, the anti – SSC performance of the pipes with high sulfur content is poor.

4). Mn element

In order to ensure the carbon content in high grade pipeline steel, manganese is usually used to improve its strength. The influence of manganese on HIC resistance of pipeline steel is mainly divided into three kinds:

a. Hot rolled line pipe steel with carbon content of 0.05 % ~ 0. 15 %

When the manganese content is 1. 0 %, the HIC sensitivity will increase abruptly:

b. For the quenched and tempered line pipe steel

When the manganese content reaches 1.6 %, the hic resistance of the steel is not significantly affected by the manganese.

c. In case carbon content is less than 0.02 %

If carbon less 0.02%, even if the manganese content exceeds 2.0%, the pipe still has good HIC resistance.

4. Hardness requirement of sour service pipe

The hardness of the sour service pipe is strict, because the hardness value has a great influence on HIC. The results show that in low and medium strength steels, the higher the material strength, the greater the hardness, the stronger the HIC sensitivity.

5. Corrosion test

In API 5L for sour service pipe, the hardness value of the base metal, weld and hot zone should not exceed 250 HV10. The hardness of the sour service pipe is more strict, because the hardness value has a greater impact on HIC. The research shows that the higher the material strength, the greater the hardness, the stronger the HIC sensitivity in low and medium strength steel.

The production of our seamless pipes is tightly regulated and all of the pipes we stock have been fully tested to international standards to ensure we only supply the highest quality products.

| Product name | Executive standard | Dimension (mm) | Steel code/ Steel grade |

|---|---|---|---|

| Black and Hot-dipped Zinc-coated Steel Pipes Seamless | ASTM A53 | 0.3-1200 x 1.0-150 | GR.A, GR.B, GR.C |

| Seamless Carbon Steel for High Temperature Service | ASTM A106 | 10.3-1200 x 1.0-150 | GR.B, GR.C |

| Seamless Cold-drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes | ASTM A179 | 10.3-426 x 1.0-36 | Low Carbon Steel |

| Seamless Carbon Steel Boiler Tubes for High Pressure | ASTM A192 | 10.3-426 x 1.0-36 | Low Carbon Steel |

| Seamless Cold-drawn Intermediate Alloy Steel Heat-exchanger and Condenser Tubes | ASTM A199 | 10.3-426 x 1.0-36 | T5, T22 |

| Seamless Medium-carbon Steel Boiler and Superheater Tubes | ASTM A210 | 10.3-426 x 1.0-36 | A1, C |

| Seamless Ferritic and Austenitic Alloy Steel Boiler, Superheater and Heat-exchanger Tubes | ASTM A213 | 10.3-426 x 1.0-36 | T5, T5b, T9 , T11, T22 ,T91 |

| Seamless Carbon and Alloy Steel for Mechanical Tubing | ASTM A333 | 1/4"-42" x SCH20-XXS | Grade1 Gr. 3,Gr..6, Gr.8 , Gr. 9 |

| Seamless Cold-drawn Carbon Steel Feedwater Heater Tubes | ASTM A556 | 10.3-426 x 1.0-36 | A2, B2 |

| Round and shaped steel cold formed welded and seamless carbon steel structural pipe. | ASTM A500 | OD :10.3-820 x 0.8- 75 | Grade A, B, C, D |

| Carbon and alloy steel mechanical tubing, either hot-finished or cold-finished | ASTM A519 | 10.3-426 x 1.0-36 | 1020, 1025, 4130, 4140 |

| For seamless ferritic alloy-steel pipe for high-temperature service | ASTM A335 | 1/4"-42" x SCH20-XXS | A/SA 335 P1, P2, P11, P12, P15, P22, P91, P92, P122 |

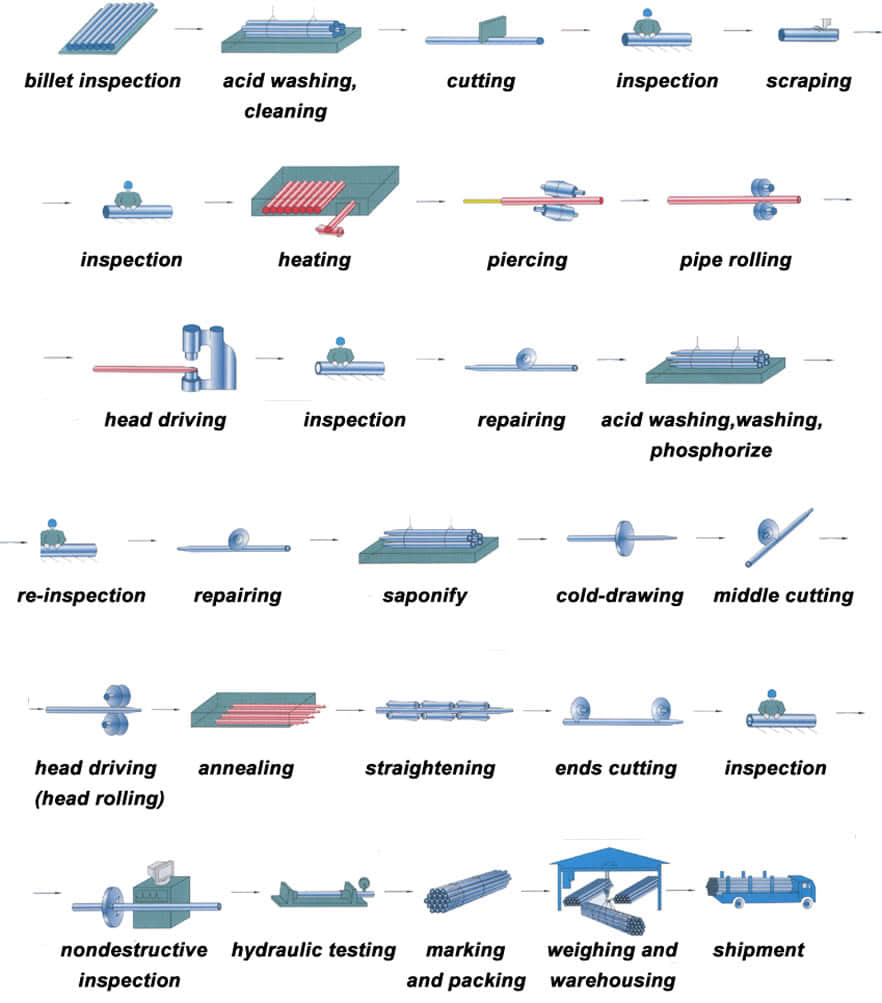

Cold Drawn Seamless Mechanical Tubing (CDS) is a cold drawn 1018/1026 steel tube which offers uniform tolerances, enhanced machinability and increased strength and tolerances compared to hot-rolled products.  Cold drawn steel tube is with hot-rolled steel coil as raw material, and tandem cold rolling pickled to remove oxide scale, its finished rolling hard roll, rolling hard volumes due to the continuous cold deformation caused by cold hardening strength, hardness increased indicators declined tough plastic, stamping performance will deteriorate, which can only be used for simple deformation of the parts. Rolling hard roll can be used as the raw material of the hot-dip galvanizing plant, hot dip galvanizing line set annealing line. Rolling hard roll weight is generally 6 to 13.5 tons, the coil diameter of 610mm.

Cold drawn steel tube is with hot-rolled steel coil as raw material, and tandem cold rolling pickled to remove oxide scale, its finished rolling hard roll, rolling hard volumes due to the continuous cold deformation caused by cold hardening strength, hardness increased indicators declined tough plastic, stamping performance will deteriorate, which can only be used for simple deformation of the parts. Rolling hard roll can be used as the raw material of the hot-dip galvanizing plant, hot dip galvanizing line set annealing line. Rolling hard roll weight is generally 6 to 13.5 tons, the coil diameter of 610mm.

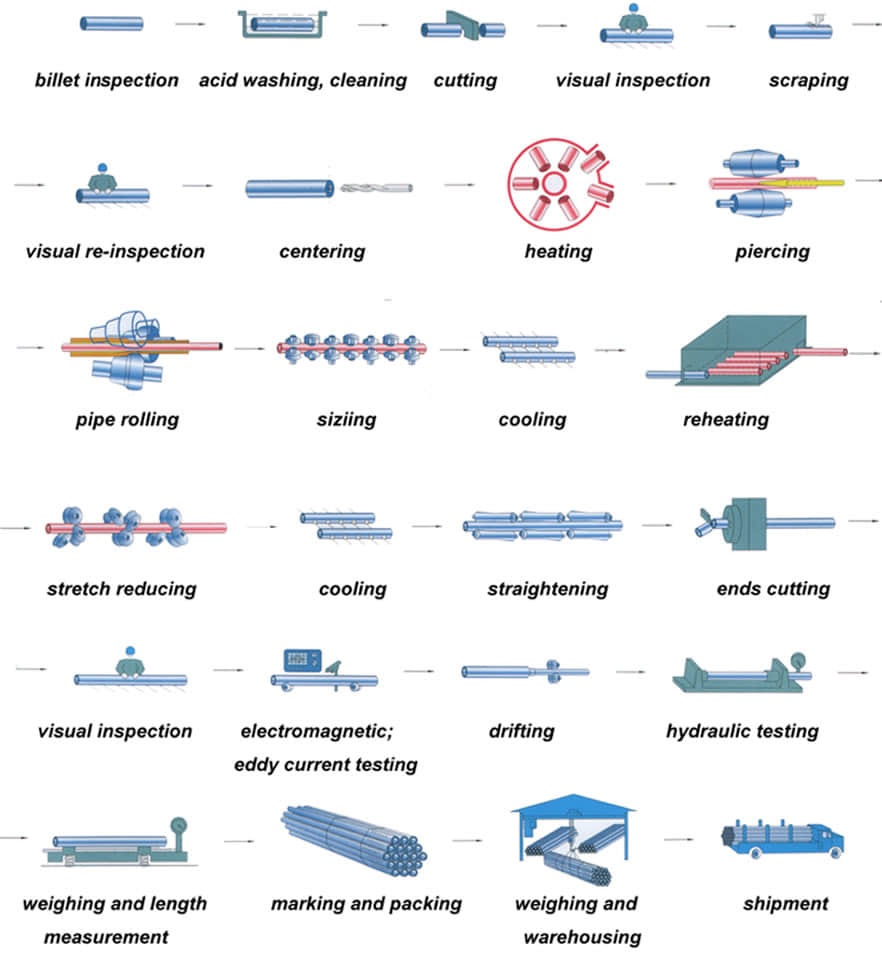

Hot-rolled seamless steel pipe production base deformation process can be summarized as three stages: perforation, extension and finishing.  The main purpose of the perforation process is to become a solid round billet piercing hollow shell. Capillary in the specifications, accuracy and surface quality can not meet the requirements of the finished product, further improvements are needed to deform the metal through. The main purpose of the stretching machine is further reduced sectional view (main compression wall) for a larger axial extension, so that the capillary improved dimensional accuracy, surface quality and organizational performance. After stretching machine rolled steel pipe shortage collectively need further molding mill in order to achieve the requirements of the finished pipe. Rolled steel due to pass in the method widely used in the production of seamless steel tubes. So far, due to the method pass rolling steel can be divided into two categories: core pension without rolling rolling (hollow body rolling), and with the mandrel. Sizing machines, reducing mill and stretch reducing mill belonging to the hole without mandrel type continuous rolling mills are generally coffin. Its main purpose is to reduce the diameter of the deformation process or sizing get finished steel, the wall thickness of process control, can make thinning, thickening or nearly unchanged. All the traditional hole-type rolling machine with mandrel belong to extend machine. The main purpose is to reduce the deformation process perforated capillary wall thickness and outer diameter roll passes in the deformation zone and the mandrel posed, for a larger axial extension. At the same time a certain improvement in the organization, performance, accuracy, surface quality.

The main purpose of the perforation process is to become a solid round billet piercing hollow shell. Capillary in the specifications, accuracy and surface quality can not meet the requirements of the finished product, further improvements are needed to deform the metal through. The main purpose of the stretching machine is further reduced sectional view (main compression wall) for a larger axial extension, so that the capillary improved dimensional accuracy, surface quality and organizational performance. After stretching machine rolled steel pipe shortage collectively need further molding mill in order to achieve the requirements of the finished pipe. Rolled steel due to pass in the method widely used in the production of seamless steel tubes. So far, due to the method pass rolling steel can be divided into two categories: core pension without rolling rolling (hollow body rolling), and with the mandrel. Sizing machines, reducing mill and stretch reducing mill belonging to the hole without mandrel type continuous rolling mills are generally coffin. Its main purpose is to reduce the diameter of the deformation process or sizing get finished steel, the wall thickness of process control, can make thinning, thickening or nearly unchanged. All the traditional hole-type rolling machine with mandrel belong to extend machine. The main purpose is to reduce the deformation process perforated capillary wall thickness and outer diameter roll passes in the deformation zone and the mandrel posed, for a larger axial extension. At the same time a certain improvement in the organization, performance, accuracy, surface quality.

Before cutting pipe and tubing No matter the material, measure the diameter of the pipe or tube to be cut to ensure that you use the right-size tube cutter for the job. When determining how to make a straight cut, use a tape measure and a pencil or other writing instrument to mark on the surface where you want to cut. If possible, mark around the circumference of a pipe, especially when cutting with a handsaw. Ensure that a cut is as straight as possible by securing the pipe with a vise, clamp, miter box or even duct tape to keep the length from shifting out of place while cutting. After cutting pipe and tubing

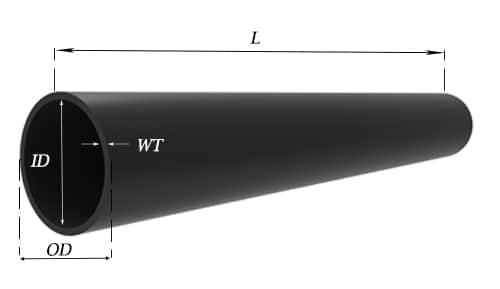

Geometrical inspection of steel pipes The outer diameter, wall thickness, bending and length of the steel pipe can be inspected on the inspection table with an outer caliper, a micrometer and a bending ruler, and a length tape measure.

Take seamless steel pipe as an example, there are some tolerances that affect quality. Noting this, and you will get a better pipe.

Weight tolerance

For pipe NPS 12 (DN300, 323.8mm) and under, the weight shall vary within -3.5% / +10%.

For pipe over NPS 12 (DN300, 323.8mm), the weight shall vary within -5% / +10%.

Pipe of NPS 4 (DN100, 114.3mm) and smaller may be weighed in convenient lots; pipe in sizes larger than NPS 4 shall be weighed separately.

Quantity tolerance

Normally mills take -10% to +10% tolerance, but TPMCSTEEL keeps ±3% variation.

Length tolerance

For Seamless pipe& tube, if definite cut lengths are ordered, the length shall vary within -0mm / +6mm.

| Pipe types | Pipe Szie(mm) | Tolerances | |

|---|---|---|---|

| Hot rolled | OD | <50 | ±0.50mm |

| ≥50 | ±1% | ||

| WT | <4 | ±12.5% | |

| ≥4-20 | +15%, -12.5% | ||

| >20 | ±12.5% | ||

| Cold drawn | OD | 6-10 | ±0.20mm |

| 10-30 | ±0.40mm | ||

| 30-50 | ±0.45 | ||

| >50 | ±1% | ||

| WT | <1 | ±0.15mm | |

| >1-3 | + 15%, – 10% | ||

| >3 | + 12.5%, – 10% | ||

| Standard | Hot finished seamless tube | Cold flnished seamless tube | ||

|---|---|---|---|---|

| Out diameter (mm) | Tolerance | Out diameter (mm) | Tolerance | |

| EN10216-1 | ≤100 | +/-0.75% (min.+/-0.5mm) | All | +/-0.5% |

| EN10216-2 | (min. +/-0.30mm) | |||

| DIN17175 | >100 | +/-0.90% | ||

| GB/T 3087 | ≤460 | +/-0.75% (min.+/-0.5mm) | 10-30 | +/-0.40mm |

| >30-50 | +/-0.45mm | |||

| >50 | +/-1.0% | |||

| GB/T 5310 GB/T 9948 GB/T 6479 | <57 | +/-0.40mm | ≤30 | +/-0.20mm |

| 57-325 | +/-0.75% | >30-50 | +/-0.30mm | |

| >325-460 | +1%,-2mm | >50 | +/-0.8% | |

| ASME SA-179M ASME SA-192M ASME SA-209M ASME SA-210M ASME SA-213M JIS G 3461 JIS G 3461 | ≤101.6 | +0.4, -0.8mm | <25.4 | +/-0.10mm |

| >25.4-38.1 | +/-0.15mm | |||

| >38.1-50.8 | +/-0.20mm | |||

| 101.6-190.5 | +0.4, -1.2mm | >50.8-63.5 | +/-0.25mm | |

| >63.5-76.2 | +/-0.30mm | |||

| >76.2 | +/-0.38mm | |||

| ASME SA106 ASME SA335 | ≤48.3 | +/-0.40mm | ≤48.3 | +/-0.40mm |

| 48.3-114.3 | +/-0.79mm | |||

| 114.4-219.1 | +1.59, -0.79mm | |||

| 219.2-323.9 | +2.38, -0.79mm | >48.3 | +/-0.79mm | |

| >324 | +/-1.0% | |||

| Standard | Hot finished seamless tube | Cold flnished seamless tube | ||||

|---|---|---|---|---|---|---|

| DIN17175 | Out diameter OD(mm) | Wall thickness T(mm) | Tolerance | Out diameter (mm) | Wall Thickness T(mm) | Tolerance |

| ≤130 | S≤2Sn | +15%, -10% | -- | All | +/-10% (min. +/-0.2mm) |

|

2Sn| +12.5%, -10% |

| |||||

| S>4Sn | +-/9% | |||||

| >130 | S≤0.05da | +17.5%, -12.5% | ||||

0.05da| +/-12.5% |

| |||||

| S>0.11da | +/-10% | |||||

| EN 10216-1 EN 10216-2 | ≤219.1 | - | +/-12.5% (min.+/-0.4mm) |

|||

| -- | T/D≤0.025 | +/-20% | ||||

0.025| +/-15% |

| |||||

0.05| +/-12.5% |

| |||||

0.1| +/-10% |

| |||||

| GB/T 3087 | -- | ≤20 | +15%,-12.5% (min.+0.45, -0.35mm) | -- | 1.0-3.0 | +15%, -10% |

| >20 | +/-12.5% | -- | >3 | +12.5%, -10% | ||

| GB/T 5310 GB/T 9948 GB/T 6479 | -- | <4.0 | +15%,-10% (min.+0.48, -0.32mm) | -- | 2-3 | +12%,-10% |

| 4-20 | +12.5%,-10% | >3 | +/-10% | |||

| >20 | +/-10% | |||||

| ASME SA-179M ASME SA-192M ASME SA-209M ASME SA-210M ASME SA-231M JIS G 3461 JIS G 3462 | -- | 2.41-3.8 | +35%, -0% | ≤38.1 | -- | +20%,-0% |

| 3.8-4.6 | +33%,-0% | >38.1 | -- | 22%,-0% | ||

| >4.6 | +28%,-0% | -- | -- | -- | ||

| ASME SA-106 ASME SA-335 | -- | All | +/12.5% | All | +/-10% | |

Note:

Positive material identification (PMI) testing is the examination of a material, usually a metallic alloy, to confirm the material is consistent with the user’s request.

Steel pipe delivery status(condition): cold / hard (BK), cold / soft (BKW), after cold stress relief annealing (BKS), annealing (GBK), normalized (NBK).

| Term | Symbol | Explanation |

|---|---|---|

| Cold-finished/hard (cold-finished as-drawn) | BK | No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

| Cold-finished/soft (lightly cold-worked) | BKW | After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

| Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

| Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

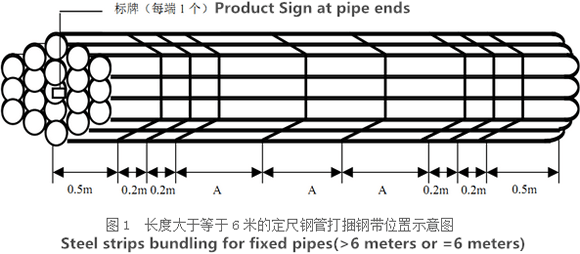

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

Our packing can meet any needs of the customers.

Need to inquire about our products? Fill out the form below and our staff will be in touch!

Q: How long is your delivery time? A: The delivery time of customized products is generally 25 35 days, and non customized products are generally shipped within 24 hours after payment. Q: Do you provide samples? Is it free? A: If the value of the sample is low, we will provide it for free, but the freight needs to be paid by the customer. But for some high value samples, we need to charge a fee. Q: What are your payment terms? A: T/T 30% as the deposit,The balance payment is paid in full before shipment Q: What is the packaging and transportation form? A: Non steaming wooden box and iron frame packaging. Special packaging is available according to customer needs. The transportation is mainly by sea. Q: What is your minimum order quantity? A: There is no minimum order quantity requirement. Customized products are tailor made according to the drawings provided by the customer.